Inventory Risk: Best Practices for Storing Stainless Steel Coils and Sheets

Storing stainless steel seems straightforward, but hidden risks can corrode your profits. We at MFY help you protect your investment with smart, effective storage strategies.

Mitigating inventory risk involves implementing climate-controlled storage to prevent corrosion, using advanced inventory management systems for accurate tracking, and adopting proper handling techniques. These practices safeguard material quality, reduce waste, and ensure supply chain efficiency, protecting your bottom line.

As the Global Business Director at MFY, I’ve seen firsthand how inventory management can make or break a project. The value of stainless steel isn't just in the raw material; it's in its pristine condition when it reaches the production line. A simple oversight in the warehouse can have costly consequences down the road. Let's break down the risks and, more importantly, the proven best practices to ensure your inventory remains a valuable asset, not a liability.

What are the common inventory risks associated with storing stainless steel coils and sheets?

Unseen storage issues can degrade valuable steel. This degradation leads to costly scrap and project delays. Let's identify these risks to protect your assets.

Common risks include physical damage from improper handling, surface corrosion from humidity, contamination from airborne particles, and financial losses due to inaccurate inventory tracking. These factors can significantly devalue your stock and disrupt operations.

In my experience, inventory risks fall into two main categories: those that attack the material itself and those that disrupt your operations. It's a dual threat that requires a comprehensive defense. I remember a client in Southeast Asia who lost nearly 15% of their stock in a single season due to unexpected atmospheric moisture. They saw it as a cost of doing business until we showed them how preventable it was. The financial and operational impacts are deeply intertwined, and understanding them is the first step toward effective mitigation.

Environmental and Physical Threats

The most immediate danger to stainless steel is its environment. Unlike what the name suggests, "stainless" steel can indeed stain or corrode under the wrong conditions. Humidity is the primary enemy. When moisture combines with salts or industrial pollutants in the air, it creates a corrosive film on the steel's surface, leading to pitting and rust. Furthermore, physical damage from poor handling, improper stacking, or equipment collisions can cause dents, scratches, and edge damage that render a coil or sheet unusable for high-spec applications.

Operational and Financial Risks

Beyond the physical state of the steel, operational risks can be just as damaging. Inaccurate inventory tracking is a major culprit. If your system doesn't provide a real-time view of what you have and where it is, you risk stockouts, overstocking, and an inability to follow a "First-In, First-Out" (FIFO) principle. This leads to older stock sitting for too long, increasing its exposure to environmental risks. The financial fallout includes the cost of wasted material, production downtime, and emergency procurement at premium prices.

| Risk Category | Specific Threat | Consequence |

|---|---|---|

| Окружающая среда | High Humidity / Moisture | Surface corrosion, rust, pitting |

| Physical | Improper Stacking / Handling | Dents, scratches, edge damage |

| Contamination | Contact with Carbon Steel | Galvanic corrosion, rust spots |

| Operational | Poor Inventory Tracking | Obsolete stock, stockouts, waste |

Why do stainless steel coils and sheets pose unique storage challenges?

You might think steel is steel. But stainless has specific needs that, if ignored, lead to failure. We understand these unique challenges and their solutions.

Stainless steel's unique challenges stem from its susceptibility to specific types of corrosion (like pitting from chlorides) and its heavy, yet delicate, surface finish. Unlike carbon steel, its value is tied to both structural integrity and aesthetic appearance.

The core challenge with stainless steel is that you're protecting more than just a metal; you're preserving a high-performance surface. For many of our clients in architecture or food processing, the aesthetic and hygienic properties are just as critical as the structural strength. This dual requirement makes storage far less forgiving than with standard carbon steel, where a bit of surface rust might be acceptable. Every scratch, stain, or water spot can mean the difference between a prime product and a piece of scrap.

The Critical Importance of the Surface Finish

The passive layer of chromium oxide[^1] on stainless steel is what gives it its corrosion resistance. This microscopic layer is strong but can be compromised. Scratches from improper handling or dragging sheets can break this layer, creating a starting point for rust. Similarly, contamination is a huge issue. Storing stainless steel near carbon steel can lead to cross-contamination, where tiny iron particles settle on the surface and cause rust spots. This is why at MFY, our warehouses have strictly segregated zones for different materials.

Weight, Shape, and Handling

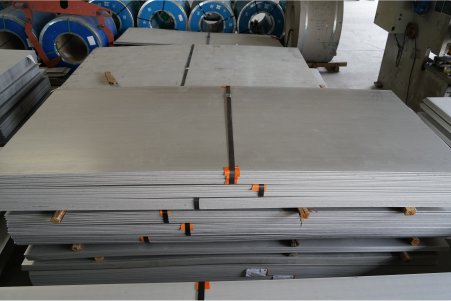

A full-sized stainless steel coil can weigh several tons. This immense weight concentrated in a cylindrical form presents significant handling and storage challenges. Improper stacking can lead to coils deforming under their own weight or causing damage to those below them. Coils must be chocked securely to prevent rolling, and sheets need to be stored flat on appropriate dunnage to prevent bending or warping. The equipment used for handling—be it forklifts with coil rams or cranes with C-hooks—must be properly maintained and operated by trained personnel to avoid damaging the material.

| Характеристика | Stainless Steel Challenge | Carbon Steel Consideration |

|---|---|---|

| Поверхность | Highly sensitive to scratches & stains | More tolerant to surface blemishes |

| Corrosion | Susceptible to chlorides & contamination | Prone to general atmospheric rust |

| Value | Tied to both function and aesthetics | Primarily functional |

| Обработка | Requires non-contaminating equipment | Standard handling often sufficient |

How does improper storage impact the quality of stainless steel products?

A small storage oversight can ruin an entire batch. This leads to rejected materials and damaged reputations. Let's explore how to prevent these quality issues.

Improper storage directly degrades quality by causing rust, pitting, and surface scratches. This compromises the material's anti-corrosive properties, aesthetic appeal, and structural integrity, rendering it unfit for its intended application and leading to significant financial loss.

The impact of poor storage is a devastating chain reaction. It starts with a seemingly minor issue—a little too much humidity in the warehouse or a single scratch from a careless forklift operator. But it never ends there. That small defect can lead to a product failing quality control, which in turn causes production delays, missed deadlines, and ultimately, a loss of trust with your customer. I've seen entire construction projects halted because the supplied stainless steel cladding showed signs of early corrosion, a problem that traced back to six weeks of improper storage at a port.

From Surface Blemish to Structural Failure

For many applications, the quality of stainless steel is defined by its flawless surface. In the food and beverage or pharmaceutical industries, any pitting or crevice caused by corrosion can harbor bacteria, making the material unsafe and non-compliant. In architectural uses, a uniform, clean finish is paramount. Any rust or staining completely negates the aesthetic purpose of using stainless steel. In more extreme cases, localized corrosion like pitting can, over time, develop into cracks that compromise the structural integrity of the component, leading to catastrophic failure in critical applications.

The Ripple Effect on Your Business

The direct cost of a rejected coil is only the beginning. You must then factor in the costs of disposal or selling it as scrap for a fraction of its value. Then come the indirect costs: the production line that sits idle waiting for replacement material, the labor costs for workers who cannot do their jobs, and the potential penalty clauses for missing a client's deadline. The most significant impact, however, is on your reputation. A company known for supplying compromised material will quickly lose its competitive edge. This is why at MFY, our quality control starts the moment raw material enters our supply chain and doesn't end until the finished product is safely delivered.

What are the effective strategies for mitigating inventory risks in stainless steel storage?

Worrying about your inventory's condition is a constant stress. This uncertainty can hurt your planning. We use proven strategies to secure your stock and peace of mind.

Effective strategies include implementing climate-controlled warehousing to manage humidity, using proper dunnage and stacking methods to prevent physical damage, and maintaining a clean, contaminant-free environment. A first-in, first-out (FIFO) system is also crucial.

Mitigation is about being proactive, not reactive. You cannot wait for rust to appear before you decide to control the humidity. At MFY, our entire warehousing philosophy is built on prevention. We invest in the right infrastructure and processes to create a stable, safe environment for our inventory. This isn't an operational cost; it's a direct investment in the quality of the product we deliver to our clients. By controlling the environment and standardizing our physical handling, we eliminate the vast majority of inventory risks before they have a chance to materialize.

Climate and Environmental Control

The single most effective strategy is to store stainless steel in a dry, climate-controlled indoor facility. The goal is to keep the relative humidity consistently below 60%. This prevents moisture from condensing on the steel's surface, which is the primary catalyst for corrosion. Temperature should also be kept relatively stable to avoid condensation cycles caused by warming and cooling. Good ventilation is important to prevent the buildup of airborne contaminants. If outdoor storage is absolutely unavoidable, the material must be covered with waterproof, breathable tarps that allow moisture to escape, and it must be elevated off the ground.

Physical Protection and Handling

Protecting the steel from physical damage is all about process. Coils and sheets should never be stored in direct contact with the ground. Use non-metallic dunnage, such as dry, untreated wood pallets, to keep them elevated and allow for air circulation. When stacking sheets, use interleaving paper to protect the surfaces from scratching each other. Coils should be stored with their axes horizontal and secured with chocks. We enforce strict rules about keeping stainless steel separate from all carbon steel products and tools to prevent iron contamination.

| Strategy | Risk Mitigated | Key Tools / Methods |

|---|---|---|

| Climate Control | Corrosion, Rust, Pitting | Dehumidifiers, HVAC systems, hygrometers |

| Proper Dunnage | Ground moisture, physical damage | Wood or plastic pallets, saddles for coils |

| Segregation | Cross-contamination | Designated storage zones, separate tools |

| FIFO System | Obsolete stock, long-term exposure | Inventory management software, clear labeling |

What are the best practices for maintaining stainless steel inventory integrity over time?

Your inventory is a long-term asset. But its value can diminish without proper care. Let's discuss the best practices for maintaining its integrity and value.

Best practices include regular inspections, a robust inventory management system (IMS) for real-time tracking, clear labeling of all stock, and comprehensive staff training on handling procedures. These ensure long-term quality and traceability.

Maintaining inventory integrity is an ongoing process, not a one-time setup. It requires a combination of technology, procedure, and people. At MFY, we see our inventory as a living part of our business. It needs constant attention and care. By integrating advanced tracking systems with rigorous, human-led processes, we create a closed-loop system that ensures every coil and sheet in our possession is accounted for, protected, and in prime condition, ready to meet our clients' exacting standards at a moment's notice.

The Power of Data: Inventory Management Systems

A modern Inventory Management System (IMS) is non-negotiable for a serious operation. An IMS provides a real-time, data-driven view of your entire stock. Every coil and sheet should be labeled with a unique identifier (like a barcode or QR code) upon arrival. This allows you to track its location, age, grade, and heat number throughout its time in your warehouse. This data is critical for implementing a strict FIFO system, ensuring that older material is used first. It also enables quick and accurate cycle counts and audits, minimizing the financial risk of inventory discrepancies.

The Human Element: Training and Procedures

Technology is only as good as the people who use it. Regular, documented training for all warehouse staff is essential. They must understand the unique properties of stainless steel and be proficient in the correct handling procedures, from operating cranes and forklifts to knowing how to properly stack and secure materials. We also implement a schedule of regular visual inspections. A trained employee should walk through the warehouse specifically looking for early signs of trouble—torn packaging, signs of moisture, or improper stacking. Catching a small problem early prevents it from becoming a large, expensive one.

| Best Practice | Objective | Ключевые действия |

|---|---|---|

| Digital Tracking | Ensure traceability and FIFO | Implement IMS, barcode every item |

| Regular Inspections | Early detection of issues | Scheduled visual checks, documented reports |

| Staff Training | Prevent human error | Formal training on handling & procedures |

| Clear Labeling | Avoid mix-ups and errors | Label with grade, size, heat number, arrival date |

Заключение

Protecting your stainless steel inventory is not an expense; it's an investment in quality and reliability. By mastering storage, you reduce risk, cut costs, and build a more resilient supply chain. MFY is here to help you achieve that.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.