A Contractor's Guide to Industrial Stainless Steel Surface Finishing

Struggling with stainless steel finishes that fail? These failures risk project compliance and client trust. Master the process to deliver durable, high-performance results every time.

Mastering industrial stainless steel surface finishing involves understanding its critical role in performance, selecting the right technique for the application, and implementing a meticulous process from preparation to maintenance. This ensures durability, compliance, and client satisfaction in demanding environments like food processing and pharmaceuticals.

As the Global Business Director at MFY, I've seen countless projects succeed or fail based on one critical, often underestimated, detail: the surface finish. It’s not just about making the steel look good. It’s about transforming a raw material into a specialized solution engineered for performance. For contractors, understanding this isn't just a technical skill; it's a significant competitive advantage. Let's break down what you need to know to deliver excellence on every project.

What Are the Basics of Stainless Steel Surface Finishing?

Confused by terms like 'passivation[^1]' and 'Ra value[^2]'? This confusion can lead to costly specification errors. Let's clarify the fundamentals for better project outcomes.

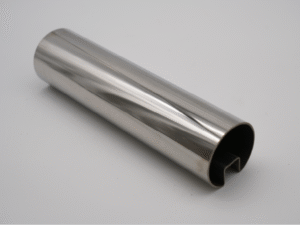

The basics of stainless steel finishing involve altering the surface to enhance properties like corrosion resistance, cleanability, and appearance. Key concepts include understanding different finish types (e.g., 2B, No. 4, electropolishing), their applications, and their impact on material performance.

In my experience, the most successful contractors are those who see surface finishing not as a final touch, but as a core engineering decision. It’s the process that directly impacts how the stainless steel will perform in its intended environment. A finish specified for an architectural feature will be completely different from one required for a pharmaceutical mixing tank, and getting it wrong can be disastrous. The right finish is fundamental to preventing corrosion, ensuring hygiene, and minimizing long-term maintenance costs for your client. It’s about delivering a product that is truly fit for purpose.

Why Finishing Matters More Than Aesthetics

The true value of a surface finish lies in its functional benefits. The smooth, passive layer created by proper finishing is what gives stainless steel its renowned corrosion resistance. In industries like food and beverage or healthcare, a specific surface roughness (Ra) is often mandated by regulations to prevent bacterial growth and ensure the surface is easily sanitized. Choosing the right finish is therefore a matter of compliance and public safety, not just looks.

Common Finish Types and Their Applications

Understanding the language of finishes is essential for clear communication with suppliers and clients. While there are dozens of specialized finishes, a few common ones form the backbone of the industry. Here is a simple breakdown we often use at MFY to guide our partners.

| Finish Name | Описание | Key Characteristics | Типовые применения |

|---|---|---|---|

| No. 2B | Smooth, moderately reflective cold-rolled finish. | General-purpose, good corrosion resistance. | Tanks, chemical equipment, food processing. |

| No. 4 | Brushed finish with visible parallel polishing lines. | Aesthetic appeal, hides minor scratches. | Kitchen equipment, architectural trim, dairy. |

| No. 8 | Highly reflective, mirror-like finish. | Superior smoothness, easy to clean. | Architectural panels, clean rooms, mirrors. |

| Electropolish | Electrochemical process to remove surface material. | Ultra-smooth, enhanced passivation, hygienic. | Pharmaceutical, semiconductor, medical. |

What Are the Key Considerations for Preparing the Surface for Finishing?

Is poor preparation ruining your finishes? Contaminants cause defects, leading to rework and delays. Proper prep is the non-negotiable first step for a flawless, durable finish.

Key considerations for preparing a stainless steel surface include thorough cleaning to remove oils and dirt, descaling to eliminate oxides from heat treatment, and ensuring the surface is free of defects like scratches or gouges. Proper preparation is foundational to achieving a high-quality, adherent finish.

You can have the best polishing equipment in the world, but if the surface isn't perfectly prepared, the final result will be compromised. I remember a project for a client in India who was fabricating large tanks for a food processing plant. They were seeing tiny rust spots appear after just a few weeks. The issue wasn't the material; it was microscopic iron particles left on the surface from a carbon steel wire brush used during preparation. It was a costly lesson for them in the importance of meticulous, stainless-specific preparation. This first step sets the foundation for the entire performance life of the component.

The Critical Role of Cleaning

The goal of cleaning is to remove any and all contaminants that could interfere with the finishing process. This includes grease, oil, cutting fluids, dirt, and even fingerprints. We recommend using alkaline cleaners or solvents that won't harm the stainless steel. The surface must be completely free of any residue before you proceed to the next step, as these contaminants can cause uneven finishing and become points where corrosion can begin.

Inspecting for Surface Imperfections

Before any abrasive or chemical process begins, a thorough visual inspection is crucial. Look for deep scratches, gouges, or weld spatter. These physical defects must be ground down and blended into the surrounding surface. If they are simply polished over, they will remain as weak points in the surface, potentially trapping contaminants and creating sites for crevice corrosion. A perfect finish can only be achieved on a perfect substrate.

What is the Step-by-Step Process for Applying Surface Finishes?

Unsure about the correct finishing sequence? An improper process can damage the material or fail to meet specs. Follow a systematic approach for consistent, reliable results.

The process generally involves mechanical abrasion (grinding, polishing) to achieve a desired roughness, followed by chemical or electrochemical treatments like pickling and passivation or electropolishing. Each step is carefully controlled to create the specified functional and aesthetic surface characteristics.

Applying a finish is a science. It's a sequence of controlled steps, each building upon the last to achieve the final specification. Rushing a step or using the wrong grit of abrasive can mean starting over from scratch. At MFY, our production lines follow strict protocols because we know that consistency is key to our clients' success. Whether it's a No. 4 brushed finish on a sheet or an electropolished pipe for a high-purity system, the process is what guarantees the outcome. Think of it as a recipe: follow the steps precisely, and you'll get a perfect result every time.

Mechanical Finishing Techniques

Most common finishes start with mechanical abrasion. This process uses abrasives (like belts, discs, or wheels) to physically alter the surface texture. The process typically moves from a coarser grit to a finer grit to progressively remove scratches and smooth the surface.

- Grinding: The initial step to remove major surface defects like welds or deep scratches. It uses coarse abrasives.

- Polishing: A refinement of the ground surface using finer abrasives to achieve a smoother, more reflective appearance, like the popular No. 4 finish.

- Buffing: The final step for mirror-like finishes (No. 8), using very fine abrasives on a cloth wheel to create a highly reflective surface.

Chemical & Electrochemical Finishing

After mechanical finishing, a chemical step is often required to restore and enhance corrosion resistance.

| Процесс | Goal | How It Works | When It's Used |

|---|---|---|---|

| Pickling | Remove heat tint and scale from welding. | Uses a strong acid (hydrofluoric/nitric) to dissolve the scale. | After welding or heat treatment. |

| Пассивация | Remove free iron and enhance the passive layer. | Uses a mild acid (nitric or citric) to enrich the surface with chromium oxide. | A final step for most finishes to maximize corrosion resistance. |

| Electropolishing | Create an ultra-smooth, clean surface. | An electrochemical process that removes a microscopic layer of surface metal. | For high-purity, hygienic applications. |

How Can You Ensure Quality and Consistency in Surface Finishing?

Do your finishes vary from batch to batch? Inconsistency undermines your reputation and can lead to project rejection. Implement robust quality control to guarantee uniformity and compliance.

Ensuring quality and consistency involves using standardized procedures, controlling variables like abrasive grit and tool speed, and employing measurement tools. Instruments like profilometers to check surface roughness (Ra) and visual inspection under controlled lighting are crucial for verification against project specifications.

Quality control is where professionalism truly shines. Anyone can polish a piece of metal, but delivering hundreds of sheets or pipes with the exact same finish requires a rigorous system. For our clients in regulated industries, "close enough" is not an option. A deviation in surface roughness can mean a failed inspection and significant project delays. This is why we invest heavily in both training our teams and equipping them with the right tools. Verifiable, repeatable quality is the bedrock of trust in the B2B materials sector. It's not an expense; it's an investment in your reputation.

Ключевые показатели эффективности

To control quality, you must be able to measure it. Simply looking at a surface isn't enough. The key metrics that define a finish must be quantified and checked against the project specifications.

- Surface Roughness (Ra): Measured in micrometers (µm) or microinches (µin), this is the average of the peaks and valleys on a surface. It is the most critical metric for hygienic applications.

- Gloss: Measures the reflectivity of a surface, important for aesthetic and architectural finishes.

- Visual Uniformity: Assesses the consistency of the finish across the entire surface, checking for streaks, defects, or color variations.

Tools of the Trade for QC

A professional quality control process relies on specialized instruments to provide objective data.

| Tool | Назначение | Почему это важно |

|---|---|---|

| Profilometer | Measures surface roughness (Ra). | Provides quantitative, verifiable proof that the finish meets hygienic or functional specs. |

| Gloss Meter | Measures the level of specular reflection. | Ensures aesthetic consistency for architectural or decorative applications. |

| Passivation Test Kit | Checks for free iron on the surface. | Verifies that the passivation process was successful and the material has maximum corrosion resistance. |

What Are the Best Maintenance Tips for Prolonging Finish Longevity?

Are your finished surfaces degrading prematurely? Improper cleaning damages the passive layer, causing corrosion. Simple, correct maintenance preserves both appearance and performance for years.

To prolong finish longevity, use non-abrasive, chloride-free cleaners with soft cloths or sponges. Clean regularly to prevent deposit buildup, always rinse with clean water, and dry the surface. Avoid harsh chemicals like bleach and steel wool, which can damage the protective passive layer.

As a contractor, your job doesn't end after installation. Providing the client with clear, simple maintenance guidelines is a crucial value-add that protects both their investment and your reputation. The most common cause of failure I see in finished stainless steel is not a material defect but improper maintenance. A maintenance worker using a carbon steel pad to scrub a tank or a cleaner using a bleach-based solution can undo all the careful work of finishing in an instant by destroying the protective passive layer. Educating the end-user is a simple step that ensures the longevity and performance you worked so hard to deliver.

Routine Cleaning Protocols

The key to long-term performance is regular, gentle cleaning. This prevents the buildup of corrosive deposits and keeps the passive layer healthy and intact. A simple routine is all that is needed.

- Use the Right Cleaner: Soap, mild detergent, or a specialized stainless steel cleaner is best. Ensure it is chloride-free.

- Use the Right Tools: A soft cloth, sponge, or microfiber towel is ideal.

- Follow the Grain: For brushed finishes (like No. 4), always wipe in the direction of the polish lines to avoid scratching.

- Rinse Thoroughly: Use clean water to remove all traces of the cleaning agent.

- Wipe Dry: Drying the surface prevents water spots and minimizes the risk of surface deposits.

What to Avoid: The "Don'ts" of Stainless Steel Care

| Do NOT Use | Why It's Harmful |

|---|---|

| Chloride-based cleaners (e.g., bleach) | Chlorides aggressively attack the passive layer, causing pitting and corrosion. |

| Steel wool or carbon steel brushes | They scratch the surface and leave behind iron particles that will rust. |

| Abrasive scouring powders | They will permanently scratch and alter the intended surface finish. |

| Leaving it dirty | Allowing dirt, grime, or industrial deposits to sit on the surface can lead to localized corrosion. |

Заключение

Mastering surface finishing transforms stainless steel from a commodity into a high-performance solution. For contractors, this expertise is not just a technical skill but a powerful competitive advantage, ensuring projects meet the highest standards of durability, compliance, and client satisfaction.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.