A Director's Guide to Stainless Steel 304, 201, 430, and 316 Coils

Choosing the right stainless steel coil can feel overwhelming, with an array of grades available. Making the wrong decision can lead to premature material failure, project delays, and significant budget overruns, ultimately impacting your bottom line and reputation. This guide will demystify the key differences.

Stainless steel 304, 201, 430, and 316 coils are defined by their unique alloy compositions, which dictate their mechanical properties and performance. Grade 316 offers superior corrosion resistance due to molybdenum, 304 is a versatile standard, 201 is an economical alternative, and 430 is a magnetic, low-cost option.

In my role as Global Business Director at MFY, I’ve seen firsthand how material selection can make or break a project. The nuances between these grades are more than just numbers on a spec sheet; they represent the difference between a durable, long-lasting product and a costly failure. This guide distills years of experience into practical insights to empower your decision-making process.

Understanding these materials isn't just an academic exercise—it's a critical business imperative. The decision between a slightly more expensive but corrosion-resistant grade like 316 and a cost-effective one like 4301 has massive implications for lifecycle costs, maintenance schedules, and brand perception. For instance, a client in the food processing industry initially considered 304 for their brine tanks to save costs, but a deeper analysis of the chloride-rich environment led us to recommend 316, preventing catastrophic failure down the line. This guide will walk you through that same critical thinking process.

What are the defining characteristics of stainless steel 304, 201, 430, and 316 coils?

Struggling to tell one stainless steel grade from another can lead to expensive mismatches in your projects. This uncertainty jeopardizes performance and durability. By understanding the core chemical and physical traits of each grade, you can confidently select the optimal material for your specific application.

The defining characteristics of these coils lie in their alloy composition. Austenitic grades 304 and 316 are rich in chromium and nickel, offering excellent corrosion resistance and formability. Grade 201 substitutes some nickel with manganese, making it more economical. Ferritic grade 430 is a low-carbon, chromium steel, making it magnetic.

Navigating the world of stainless steel requires a firm grasp of the fundamental properties that distinguish one grade from another. It's a conversation I have daily with partners, from engineering contractors in the Middle East to manufacturing firms in Southeast Asia. They all face the same initial challenge: decoding the spec sheets to understand what the material will actually do. The numbers representing chromium, nickel, molybdenum, and manganese content are not just abstract figures; they are the genetic code of the steel, dictating its strength, its resistance to rust, its ability to be shaped and welded, and even its appearance. For example, the higher nickel content in 304 compared to 201 directly translates to superior ductility and corrosion resistance, a vital detail for a client producing high-end kitchen sinks. Conversely, the presence of molybdenum in 316 is a non-negotiable requirement for another client manufacturing components for marine environments. Understanding these defining characteristics is the first and most critical step in building a resilient and efficient supply chain. It moves the conversation from "what's cheapest?" to "what delivers the best long-term value?", a shift in perspective that we at MFY champion.

The journey into material specification is one of precision. A slight variation in chemical makeup can lead to a vastly different performance profile, impacting everything from manufacturing processes to the end-product's lifecycle. We must move beyond surface-level comparisons and delve into the science that governs each grade's behavior. This deeper understanding prevents costly assumptions and empowers you to build with confidence, knowing your material choice is backed by data and a clear comprehension of its intrinsic strengths and weaknesses. It's about matching the steel's DNA to the project's unique environmental and mechanical demands.

The Austenitic Workhorses: Grades 304 and 316

Grades 304 and 316 belong to the austenitic family of stainless steels, a classification defined by their face-centered cubic crystal structure. This structure, primarily achieved through the generous addition of nickel, renders them non-magnetic and gives them their renowned combination of strength, formability, and weldability. Grade 304, often referred to as 18/8 stainless, contains approximately 18% chromium and 8% nickel. This composition provides excellent resistance to a wide range of atmospheric and chemical corrosives, making it the most widely used stainless steel grade globally.

The key differentiator for Grade 316 is the addition of molybdenum, typically around 2-3%. This element significantly enhances its resistance to corrosion, particularly against chlorides and other industrial solvents. This makes it an indispensable material in harsh environments. I recall a project with an engineering contractor in the UAE who was designing a coastal desalination plant. While 304 was initially considered for piping, our analysis proved that the high salinity and chloride exposure would lead to pitting corrosion within a few years. By switching to 316, the client secured a much longer service life and avoided the immense costs of future repairs and downtime, illustrating the critical importance of matching the alloy to the specific environmental challenge.

The practical implications of these compositions extend into manufacturing. Both grades exhibit excellent weldability and can be deep-drawn, making them suitable for complex shapes like tanks, sinks, and intricate architectural panels. However, the higher nickel and molybdenum content in 316 can make it slightly more challenging to machine than 304. At MFY, we often advise clients on the subtle adjustments needed in tooling and cutting speeds to optimize production when working with 316, ensuring that its superior properties don't come at the cost of manufacturing efficiency. This holistic approach, from raw material chemistry to final fabrication, is crucial for success.

The Economic Contender: Grade 201

Grade 201 is also an austenitic stainless steel, but it represents a clever piece of material engineering aimed at cost reduction. In its composition, metallurgists have intentionally substituted a portion of the expensive nickel content with more affordable elements, namely manganese and nitrogen. This balancing act creates a material that retains the austenitic, non-magnetic structure but at a lower price point. While its chromium content is comparable to 304, the reduced nickel means its corrosion resistance is generally lower, making it unsuitable for outdoor or chemical-heavy applications.

This cost-conscious composition makes Grade 201 a popular choice for interior applications where aesthetics are important but the environment is benign. We worked with a large-scale distributor in India whose clients manufacture a wide range of household goods, from decorative trim and furniture components to indoor railings. For them, Grade 201 coils provided the perfect balance. They get the bright, clean look of stainless steel and good formability for their manufacturing processes, without paying the premium for the high nickel content of 304, which would be overkill for the application.

However, it is crucial to understand the trade-offs. The higher manganese content in Grade 201 can result in increased work hardening compared to 304, meaning it becomes harder and stronger more quickly during forming processes. This requires more powerful machinery or can limit the complexity of the shapes that can be formed. We always stress this point to new clients considering a switch from 304 to 201 to manage costs. It’s not a simple one-for-one replacement; it requires a careful review of their manufacturing capabilities to ensure a smooth and successful transition.

The Ferritic Specialist: Grade 430

Unlike the 300 and 200 series, Grade 430 is a ferritic stainless steel. This means it has a body-centered cubic crystal structure and, most notably, is magnetic. Its composition is fundamentally different, consisting primarily of chromium with a very low carbon content and, crucially, almost no nickel. This nickel-free formula makes Grade 430 significantly less expensive than its austenitic counterparts, positioning it as a strong candidate for cost-driven projects. Its primary strength lies in its good corrosion resistance in mild atmospheric conditions and its resistance to oxidation at elevated temperatures.

The applications for 430 are widespread, particularly in environments where it won't be exposed to aggressive corrosives. A classic example comes from one of our manufacturing clients who produces kitchen appliances. They use MFY’s 430 coils for refrigerator panels, dishwasher linings, and stovetops. The material's magnetism is an advantage for refrigerator doors, its aesthetic appeal meets consumer expectations, and its resistance to food acids and cleaning agents is perfectly adequate for the application. This allows them to deliver a durable, attractive product while maintaining a competitive price point in the market.

It is essential, however, to recognize its limitations. Grade 430's weldability is considered fair, but it's not as robust as the 300 series; the welds can be more brittle. Furthermore, its formability is lower than that of Grade 304, so it is less suitable for applications requiring severe deep drawing. A client learned this when they tried to use 430 for a complex automotive trim part that required significant stretching, leading to cracking. We guided them to switch back to 304 for that specific component, reinforcing the lesson that the lowest material cost does not always equal the lowest total project cost.

| Класс | Key Elements | Crystal Structure | Magnetic? | Относительная стоимость |

|---|---|---|---|---|

| 304 | ~18% Cr, ~8% Ni | Austenitic | No | Средний и высокий |

| 316 | ~17% Cr, ~10% Ni, ~2% Mo | Austenitic | No | Высокий |

| 201 | ~17% Cr, ~4% Ni, ~6% Mn | Austenitic | No | Средний |

| 430 | ~17% Cr, <0.75% Ni | Ferritic | Yes | Низкий |

316 has superior chloride resistanceПравда

The 2-3% molybdenum content in 316 significantly enhances its resistance to chlorides, making it ideal for marine environments.

430 is non-magneticЛожь

As a ferritic stainless steel, Grade 430 has a body-centered cubic structure that makes it magnetic, unlike austenitic grades.

How do the properties of these stainless steel coils impact their use in different industries?

Choosing a material without understanding its industrial application is like sailing without a compass. You might save on initial costs, but you risk catastrophic failure when the material can't withstand its operational environment. Aligning the specific properties of each steel grade with industry demands is essential.

The distinct properties of each stainless steel grade directly govern its suitability for specific industries. Grade 316 stainless steel's superior corrosion resistance is vital for marine and chemical processing. Grade 304's balanced performance and formability make it a staple in food processing and architecture. Grade 201's economy suits indoor appliances, while 430's magnetic nature is key for certain equipment.

The conversation about material properties must always be grounded in the context of real-world application. At MFY, we don't just sell steel; we provide solutions tailored to specific industrial challenges. A client in the demanding oil and gas sector will have a completely different set of requirements than a manufacturer of consumer electronics. The former needs materials like 316 that can withstand extreme pressures, temperatures, and corrosive substances, where material failure is not an option. The latter might prioritize the aesthetic finish and cost-effectiveness of a grade like 430 for a product with a shorter lifecycle in a controlled environment. My experience across these diverse sectors has shown that a property like "corrosion resistance" isn't a single data point; it's a spectrum. The question is never "is it resistant?" but "is it resistant enough for this specific environment?" This nuanced understanding is what separates a reliable supplier from a mere trader. It involves a deep dive into the client's processes, from fabrication methods that test the steel's formability and weldability, to the end-use conditions that challenge its durability and strength over time.

This philosophy of application-centric material selection is the bedrock of a successful and sustainable supply chain. It's about creating a partnership where we, as the supplier, understand the client's industry so well that we can anticipate their needs and guide them to the most efficient and effective solution. Whether it's providing 304 coils with a specific finish for an architectural project or supplying high-strength 201 for structural components in indoor equipment, the goal is the same: to ensure the steel's inherent properties are perfectly aligned with the demands of its industry, guaranteeing performance, safety, and long-term value. This is the expertise we bring to every transaction.

The Unyielding Choice for Harsh Environments: Grade 316

In industries where materials face a constant barrage from corrosive elements, Grade 316 is not just a preference; it's a necessity. The key to its dominance in sectors like marine, chemical processing, and pharmaceuticals is its molybdenum content. This element provides robust resistance to pitting and crevice corrosion caused by chlorides, which are abundant in seawater, de-icing salts, and many industrial chemicals. Without this specialized protection, equipment would degrade rapidly, leading to safety hazards, costly shutdowns, and environmental risks.

Consider the case of a valued MFY partner, a major engineering and construction contractor specializing in coastal infrastructure in Southeast Asia. They were tasked with building a new pier and support facilities. The constant spray of saltwater and high humidity created an extremely aggressive corrosive environment. Using a lower grade like 304 would have been a short-sighted economy, as it would have shown signs of rust and structural weakening in a fraction of the desired lifespan. By specifying MFY’s 316 stainless steel coils for all structural elements, railings, and fixtures, they ensured the project would meet its 50-year design life, safeguarding their reputation and delivering long-term value to their client.

The same principle applies in the pharmaceutical industry, where cleanliness and resistance to aggressive cleaning agents are paramount. A manufacturer of sterile mixing vessels relies on our 316L (a low-carbon variant) coils. The material must withstand repeated sterilization cycles with harsh chemicals without leaching any elements or developing surface imperfections where bacteria could harbor. The superior chemical stability of Grade 316 ensures the integrity of the end product, a non-negotiable requirement where public health is at stake. Its higher initial cost is insignificant compared to the immense cost of a contaminated batch or product recall.

The All-Rounder for Food, Beverage, and Architecture: Grade 304

Grade 304 has earned its title as the workhorse of the stainless steel world due to its remarkable balance of properties. Its excellent corrosion resistance is more than sufficient for the vast majority of applications, it is readily formed and welded, and it presents a clean, hygienic surface that is easy to maintain. This combination makes it the go-to material for the food and beverage industry, where it is used for everything from storage tanks and piping to food preparation surfaces and processing equipment.

I remember working with a growing beverage company that was expanding its production line. They needed tanks, vats, and tubing that would not react with their products, ensuring that the taste and quality of their drinks remained pure. Furthermore, the material had to withstand daily cleaning protocols involving various detergents and sanitizers. Grade 304 was the perfect solution. Its proven performance in these conditions gave the client peace of mind, while its excellent formability allowed for the custom fabrication of tanks and complex piping systems to fit their specific plant layout. MFY supplied the 2B finish coils that provided a smooth, non-porous surface ideal for their hygiene requirements.

In the world of architecture, Grade 304 is prized for both its durability and its aesthetic versatility. It can be finished in numerous ways—from a bright, reflective polish to a muted, brushed satin—allowing architects to achieve their desired visual effect. We supplied a significant quantity of 304 coils to a contractor for the facade of a new commercial tower. The material had to withstand urban pollution and weather while retaining its pristine appearance for decades. Grade 304 delivered on this promise, providing a modern, sleek look that was also a practical, low-maintenance choice, demonstrating its ability to bridge the gap between artistic vision and engineering reality.

Cost-Effective Solutions for Consumer & Interior Applications: Grades 201 & 430

In the highly competitive consumer goods market, cost is a primary driver. Manufacturers must deliver functional, attractive products at a price point the market will accept. This is where the economic advantages of Grades 201 and 430 come to the forefront. These grades allow for the use of genuine stainless steel in applications where the high performance of 304 or 316 would be unnecessary and cost-prohibitive. They are the engine of affordability in the industry.

Grade 201, with its lower nickel content, is a star player in indoor environments. We have a long-standing relationship with a client who is a leading manufacturer of kitchenware and hollowware in India. They produce pots, pans, and utensils that require good formability and a bright finish. For them, Grade 201 is the ideal choice. It provides the necessary strength and corrosion resistance to handle daily cooking and cleaning, but at a material cost that allows them to compete effectively. Their ability to manage costs through smart material selection, using 201 for the main body and perhaps a different grade for other components, is key to their business model.

Similarly, Grade 430 finds its niche in appliances and decorative trim. Its key advantage is its low cost combined with its magnetic properties. A manufacturer of kitchen range hoods, for example, uses our Grade 430 stainless steel2 coils extensively. The material offers sufficient corrosion resistance for a kitchen environment, polishes to a beautiful finish, and is easily formed into the required shapes. Its magnetism is often irrelevant for the application, but its price point is extremely relevant to the product's final cost. By selecting 430, they avoid the nickel premium entirely, passing those savings on to the consumer and capturing a larger market share. This strategic use of materials demonstrates a sophisticated understanding of balancing performance, aesthetics, and economics.

316 resists chloride corrosionПравда

Grade 316 contains molybdenum which provides superior resistance to pitting and crevice corrosion caused by chlorides in seawater and chemicals.

304 is unsuitable for food industryЛожь

Grade 304 is actually the preferred choice for food processing due to its hygienic surface, corrosion resistance and easy cleanability.

What factors should be considered when choosing between 304, 201, 430, and 316 stainless steel coils?

Making the wrong material choice can lead to hidden costs, from difficult fabrication to premature product failure. You need a clear framework to avoid these pitfalls. By systematically evaluating key factors, you can ensure your selection is the most cost-effective and reliable for your project's entire lifecycle.

When choosing between these grades, consider five factors: the corrosive nature of the service environmentservice environment impact on stainless steel, required mechanical properties (strength, ductility)mechanical properties comparison, fabrication processes (welding, forming), the total lifecycle cost including maintenance, and any aesthetic requirements for the final product's finish.

Selecting the right stainless steel coil is a multi-faceted decision that extends far beyond the initial price per kilogram. As a supplier, my goal is to guide clients toward the most logical and valuable long-term choice. This requires a holistic analysis of their project. We begin with the most critical factor: the operational environment. Is the steel going to be indoors or outdoors? Will it be exposed to salt, chemicals, or extreme temperatures? Answering this question immediately narrows the field. A manufacturer of indoor furniture can confidently use 201, while an offshore oil rig absolutely cannot. Next, we discuss fabrication. Does the design require deep drawing or complex welding? The superior formability of 304 might be essential, whereas the brittle nature of 430 weldsissues with 430 welds3 could disqualify it. I’ve seen projects where a cheaper material was chosen, only to have costs balloon due to high scrap rates and fabrication difficulties. This is why we emphasize understanding the total cost of ownership, not just the purchase price. This includes installation, potential for maintenance or repair, and the expected service life. This comprehensive approach transforms material purchasing from a simple transaction into a strategic investment in the project's success.

Ultimately, this decision-making process is a balancing act. It’s about weighing the technical requirements against the commercial realities. At MFY, we see our role as a consultant in this process. We bring our deep knowledge of material science and our experience across countless applications to the table. We help clients quantify the risks and rewards of each option, enabling them to make an informed decision that aligns with their performance goals, manufacturing capabilities, and budget. It’s a collaborative effort to build something that is not only functional and beautiful but also economically sound and built to last.

Factor 1: Corrosion Resistance and Environmental Exposure

The single most important factor in stainless steel selection is matching the grade's corrosion resistance to its service environment. A failure in this area is often the most catastrophic and costly. The primary consideration is the presence of corrosive agents. The most common enemy is chloride, found in marine atmospheres, de-icing salts, and many industrial chemicals. This is where the distinction between grades becomes starkly clear. Grade 316, with its molybdenum contentspecial role of molybdenum in grade 3164, is specifically designed to resist chloride pitting and is the default choice for marine and many chemical processing applications.

Grade 304 offers excellent general-purpose corrosion resistance, making it suitable for a vast range of applications, including kitchens, food processing, and architectural use in non-coastal areas. It withstands oxidation and is resistant to most oxidizing acids. However, it is susceptible to chloride attack. I once consulted on a project for architectural cladding on a building located just a few kilometers from the coast. The client was leaning towards 304 to save on cost. We ran an analysis showing that even airborne saline humidity could lead to "tea staining" and pitting over time, requiring expensive cleaning and potentially replacement. The slightly higher initial investment in 316 was easily justified as a long-term saving.

Grades 201 and 430 have more limited corrosion resistance. Grade 201, with its reduced nickelnickel content impact in grade 2015, is best suited for dry, indoor environments where it won't be exposed to moisture or corrosive chemicals. It's a great choice for decorative items or internal structural parts. Grade 430 offers good resistance to mild corrosives like fresh water and food acids, hence its use in kitchen appliances, but it will rust in more aggressive conditions. Misusing these grades in outdoor or industrial settings is a common mistake that leads to rapid failure, tarnishing not only the steel but also the manufacturer's reputation.

Factor 2: Mechanical Properties and Fabrication Requirements

Beyond corrosion, the mechanical properties of the steel and the demands of the fabrication process are critical. Key properties include ductility (the ability to be drawn into shapes), tensile strength (resistance to being pulled apart), and hardness. The austenitic grades, 304 and 316, are renowned for their excellent ductility and formability. This makes them ideal for products requiring significant shaping, such as deep-drawn kitchen sinks, complex automotive exhaust components, or stamped parts.

Grade 304 is often seen as the benchmark for formability. However, the slightly higher nickel content in 316 can make it marginally less formable, and both grades are susceptible to work hardeningstrategies for managing work hardening6, which must be managed during multi-stage forming operations. We had a client manufacturing intricate-stamped industrial components who was struggling with cracking issues. They were using a standard 304 grade. We analyzed their process and recommended a switch to a specific variant of 304 with a slightly adjusted composition to improve its deep-drawing quality (DDQ), which immediately solved their problem and reduced their scrap rate by over 15%.

Grade 201 also has good formability but tends to work-harden more rapidly than 304 due to its higher manganese and nitrogen content. This means it might require more powerful presses or intermediate annealing steps for very complex parts. Grade 430, being a ferritic steel, has more limited ductility. It can be bent and formed, but it is not suitable for severe deep drawing. Similarly, welding presents differences. Austenitic grades are generally easy to weld, creating strong, ductile joints. Ferritic 430 can be welded, but the resulting weld is more brittle and may require post-weld heat treatment to restore ductility, adding complexity and cost to the manufacturing process.

Factor 3: Total Lifecycle Cost vs. Initial Purchase Price

A common mistake I see is focusing solely on the initial purchase price of the steel coil. A truly sound business decision considers the Total Lifecycle Cost (TLC)total lifecycle cost in stainless steel projects7, which encompasses the initial material cost, fabrication costs, installation, maintenance, and the expected service life of the product. A cheaper material that fails prematurely or requires frequent maintenance can quickly become far more expensive than a higher-grade alternative. This is a conversation we at MFY have constantly with our partners, especially those in the engineering and construction sectors.

Let's consider a practical example: building a public walkway railing. Option A uses Grade 201 coils, which has the lowest initial cost. Option B uses Grade 304. In an indoor, controlled environment like a shopping mall, Option A is perfectly viable and the most economical choice. However, if this railing is for an outdoor bridge in a city with moderate rainfall and pollution, the 201 grade will likely show signs of rust within a few years. This will necessitate costly manual cleaning, polishing, or even eventual replacement. The Grade 304 railing, while costing more initially, would withstand the environment for decades with minimal maintenance. The TLC of the 304 option is therefore significantly lower.

This analysis becomes even more critical when using Grade 316. A chemical plant installing a new piping system might balk at the price of 316 compared to 304. However, if the alternative is a plant shutdown for pipe replacement every five years due to corrosion failure from 304, the economic case for 316 is overwhelming. The cost of lost production during that shutdown could exceed the initial material cost difference many times over. Therefore, a smart purchasing manager or engineer doesn't ask "What is the price?", they ask "What is the cost over 20 years?".

| Фактор | Марка 304 | Grade 316 | Grade 201 | Grade 430 |

|---|---|---|---|---|

| Устойчивость к коррозии | Превосходно | Superior | Ярмарка | Good (Mild) |

| Формуемость | Превосходно | Очень хорошо | Хорошо | Ярмарка |

| Свариваемость | Превосходно | Превосходно | Хорошо | Ярмарка |

| Первоначальная стоимость | Средний и высокий | Высокий | Средний | Низкий |

| Best Environment | General Purpose, Food, Arch. | Marine, Chemical, Medical | Indoor, Decorative | Appliances, Dry Interior |

316 resists chloride corrosionПравда

Grade 316 contains molybdenum which provides superior resistance to chloride pitting, making it ideal for marine environments.

430 is best for marine useЛожь

Grade 430 has limited corrosion resistance and will rust in marine environments; 316 is the proper choice for saltwater exposure.

Which applications benefit most from each type of stainless steel coil?

Using the wrong grade of steel is like using the wrong tool for a job—inefficient and potentially dangerous. This mismatch can lead to underperformance and failure. By clearly mapping each steel grade8 to its ideal applications, you can ensure optimal performance, safety, and cost-effectiveness for your products.

Each stainless steel grade excels in specific applications. Grade 316 is ideal for marine hardware, chemical tanks, and medical implants. Grade 304 thrives in kitchen equipment, architectural facades, and automotive systems. Grade 201 is best for indoor decorative trim and utensils, while 430 is perfect for refrigerator panels and industrial strapping.

The true art of stainless steel supply lies in precision matching—aligning the unique character of each grade with the specific demands of an application. It's a process I've honed over years of collaborating with clients across dozens of industries. It’s not about having a favorite grade; it’s about having the right grade for the right reason. When a client comes to us, we don’t just take an order for a certain tonnage of steel. We engage in a dialogue. We ask about the end product, its environment, the manufacturing stresses it will undergo, and the client's commercial goals. This consultative approach prevents costly errors. I’ve seen companies specify 304 for a poolside application out of habit, not realizing the high chlorine environment would demand 316. Conversely, I’ve seen others over-specify 316 for a simple indoor decorative panel, a situation where 201 or 4309 would have performed identically at a fraction of the cost. These seemingly small decisions have a massive ripple effect on a project's profitability and a product's reputation. Our mission at MFY is to provide that critical layer of expertise, ensuring every coil we ship is not just a commodity, but the perfect foundation for our client's success.

This application-specific mindset is crucial for our clients, who range from massive construction contractors to nimble manufacturers. For a distributor, understanding these applications allows them to manage their inventory intelligently, stocking the grades that are most relevant to their customer base. For a manufacturer, it allows them to design products that are both competitive and durable. For an engineering firm, it is the basis of safe and reliable infrastructure design. By breaking down the ideal use-cases for each grade, we can move from abstract technical data to concrete, actionable intelligence that drives better business outcomes for everyone in the value chain.

Grade 316: The Champion of Extreme Conditions

Grade 316's exceptional resistance to corrosion, particularly against chlorides and acids, makes it the undisputed champion for the most demanding applications. Its use is not a luxury but a requirement in environments where material failure could have severe consequences. The marine industry is a prime example. Every component on a ship or offshore platform, from rigging and railings to fasteners and heat exchangers, is relentlessly attacked by saltwater. Here, Grade 316 is the baseline for ensuring structural integrity and operational safety.

In the chemical and petrochemical sectors, the story is the same. Storage tanks, piping systems, and reactors often contain highly corrosive substances at elevated temperatures and pressures. A client of ours who manufactures specialty chemicals relies exclusively on our 316L coils for their processing vessels. The 'L' signifies low carbon, which improves weldability and reduces the risk of sensitization—a form of corrosion that can occur at the weld joints. The use of 316L10 ensures the purity of their chemical products and prevents catastrophic leaks that could harm personnel and the environment.

The medical field also depends heavily on Grade 316. Its high biocompatibility and resistance to corrosion from bodily fluids make it a preferred material for surgical implants, such as bone fixation screws and plates, as well as high-quality surgical instruments. The material must be completely inert, ensuring it doesn't react with the body or degrade over time. In these life-critical applications, the superior performance and reliability of Grade 316 are non-negotiable, and its higher cost is a small price to pay for patient safety and device efficacy.

Grade 304: The Versatile Backbone of Modern Industry

If Grade 316 is the specialist, Grade 304 is the indispensable all-rounder. Its fantastic balance of cost, corrosion resistance, and fabricability has made it the backbone of countless modern industries. It is arguably the most common stainless steel grade you encounter daily. The entire food and beverage industry is built upon it. From the massive brewing tanks at a brewery to the stainless steel counters and equipment in a commercial kitchen, Grade 304 provides a hygienic, easy-to-clean, and non-reactive surface that ensures food safety.

In architecture and construction, Grade 304 is celebrated for its aesthetic flexibility and durability. It's used for everything from stunning building facades and roofing to elegant interior handrails and elevator panels. We recently supplied a large volume of 304 coils with a brushed finish to a contractor building a new airport terminal. The choice provided a sleek, modern aesthetic that could withstand the high traffic of a public space while requiring minimal maintenance, proving its value in large-scale infrastructure projects.

The automotive industry also relies heavily on Grade 304, particularly for exhaust systems, grilles, and trim. In an exhaust system, the steel must withstand high temperatures, corrosive exhaust gases, and external road salts. Grade 304 offers a cost-effective solution that provides a significantly longer lifespan than traditional carbon or aluminized steel. Its ability to be easily formed into complex shapes allows for the design of efficient and compact exhaust systems that meet modern performance and emissions standards.

Grades 201 & 430: Driving Affordability in High-Volume Markets

The greatest benefit of Grades 201 and 430 is their ability to make stainless steel accessible in cost-sensitive, high-volume markets. They enable manufacturers to offer the desirable qualities of stainless—its look, cleanliness, and durability—at a more competitive price point. Grade 201, the economical austenitic option, has found a massive market in consumer goods, especially in developing economies. It is the material of choice for affordable household items.

A prime example is a client in Southeast Asia who is one of the region's largest producers of cookware and utensils. By using MFY's 201 coils, they can mass-produce durable, attractive kitchen products that are affordable for a broad consumer base. For an indoor application like a cooking pot, the corrosion resistance of 201 is perfectly adequate. This smart material choice allows our client to dominate their market segment, providing quality products to millions of households. The same principle applies to indoor decorative tubing, furniture frames, and appliance trim.

Grade 430, the low-cost ferritic steel, serves a similar purpose but with different strengths. Its primary application benefit is found in the home appliance sector. As I mentioned before, it is the standard for magnetic refrigerator and freezer doors. Beyond that, its excellent performance in dry, indoor heat makes it ideal for the internal components and housings of toasters, ovens, and space heaters. It's also widely used for industrial strapping, where its strength and low cost are the key drivers. For these applications, the high-end corrosion resistance of a 300-series grade would be an unnecessary expense, and 430 delivers all the required functionality.

316L is used for medical implantsПравда

316L's biocompatibility and corrosion resistance make it ideal for surgical implants that must remain inert in the human body.

304 is suitable for marine applicationsЛожь

304 lacks sufficient chloride resistance for marine environments, where 316 is the required grade.

What are the key considerations for handling and maintaining stainless steel coils?

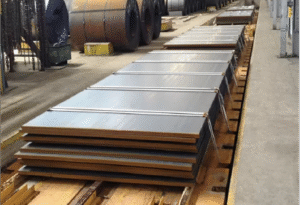

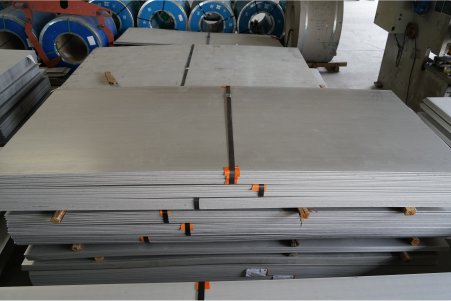

Improper handling and maintenance can ruin even the highest quality stainless steel, leading to scratches, contamination, and corrosion. This negates your investment and can cause premature failure. Understanding proper procedures is vital to protect the material's integrity from delivery to its final application.

Key considerations for stainless steel coils include using proper lifting equipment to avoid surface damage, storing them in a dry, clean environment to prevent contamination, using dedicated tools to avoid iron cross-contamination, and following a cleaning regimen appropriate for the specific grade and environment.

From the moment a stainless steel coil leaves our facility at MFY to its final installation, its pristine condition is at risk. Handling and maintenance are not afterthoughts; they are critical stages that preserve the material's inherent properties. I’ve seen beautiful, high-grade 316 stainless steel coils11 arrive at a construction site only to be mishandled. Stored outdoors in the mud, lifted with carbon steel chains that scratch the surface and embed iron particles, the material is compromised before a single weld is made. These embedded iron particles become nucleation sites for rust, completely negating the reason for choosing stainless steel in the first place. This is why we educate our clients on best practices with the same rigor we apply to material selection. Proper handling is the first line of defense in ensuring the longevity and performance of the final product. It involves a disciplined approach to storage, lifting, fabrication, and cleaning. A small investment in the right procedures pays huge dividends in the long-term performance and appearance of the steel, protecting the integrity of the project and the reputation of the builder.

The maintenance aspect is equally crucial and is dictated by the grade and the environment. A 430 stainless steel refrigerator panel12 may only need wiping with a soft cloth and mild detergent. In contrast, a 316 architectural facade on a coastal building may require periodic freshwater rinsing to wash away accumulated salt deposits to prevent staining and ensure it looks its best for decades. Developing a proactive, appropriate maintenance plan is far more effective and less costly than reacting to problems like rust or staining after they appear. Our role as a responsible supplier extends to providing this guidance, ensuring our clients can maximize the value of their investment for years to come.

Protecting the Surface: Handling and Storage

The preservation of a stainless steel coil's surface begins the moment it is received. The protective film applied at the mill is the first barrier, but physical handling poses the greatest risk. Coils should always be lifted using equipment designed for the task, such as wide, padded slings or C-hooks with protective surfaces. Using carbon steel chains or hooks is strictly forbidden, as they can scratch the surface and, more importantly, embed ferrous particles that will lead to localized rust spots, a phenomenon known as "iron contamination."

Storage protocols are equally vital. Stainless steel coils must be stored in a clean, dry, and preferably covered environment. Laying them directly on the ground, especially outdoors, exposes them to moisture, dirt, and industrial pollutants that can compromise the passive layer—the invisible chromium oxide film that gives stainless steel its corrosion resistance. A client of ours, a fabricator of architectural panels, invested in a dedicated storage rack system that keeps the coils off the floor and separated by grade. This simple step eliminated issues they previously had with surface contamination and scratches, improving their product quality and reducing rework costs.

It is also critical to keep different metals segregated in the workshop. Carbon steel dust from grinding or cutting operations can settle on the surface of stainless steel and cause contamination. Many top-tier fabrication shops dedicate specific areas or even entire buildings exclusively to stainless steel work. They use separate tools—grinders, brushes, and handling equipment—for stainless steel to prevent cross-contamination. This level of discipline is essential to maintaining the integrity of the material throughout the fabrication process.

Best Practices in Fabrication

During fabrication, the primary goal is to maintain the steel's corrosion resistance, which can be compromised by heat and contamination. When welding austenitic grades like 304 and 316, it is important to use the correct filler metal (e.g., 308L for 304, 316L for 316) and to control heat input. Excessive heat can lead to "sensitization," where chromium carbides form at the grain boundaries, depleting the surrounding area of the chromium needed for corrosion protection. This creates a risk of intergranular corrosion, especially in the heat-affected zone next to the weld.

After welding, proper post-weld cleaning is not optional; it is mandatory. This involves removing the heat tint or "weld scale" that forms during welding, as this layer has a lower chromium content and is a potential site for corrosion. This is typically done through mechanical methods like grinding or brushing (with stainless steel brushes only) or, more effectively, through chemical methods like pickling and passivation. Pickling uses an acid solution to remove the scale, while passivation is a milder acid treatment that helps restore the chromium oxide passive layer. We worked with a manufacturer of food processing equipment who implemented a stringent post-weld passivation process for all their products, a step that significantly enhanced the longevity and hygiene of their equipment.

Cutting and forming also require care. Whether using shears, plasma cutters, or lasers, the goal is to get a clean cut without excessive heat or contamination. Any tooling that comes into contact with the stainless steel should be clean and dedicated to that material. Using a tool that was just used on carbon steel can transfer iron particles onto the stainless part, creating a future rust problem. This attention to detail at every stage of fabrication is what separates high-quality products from those that fail prematurely.

Long-Term Maintenance and Cleaning

The maintenance required for a stainless steel product depends entirely on its grade and its exposure. A common misconception is that stainless steel is "maintenance-free." A more accurate term is "low-maintenance." All grades benefit from periodic cleaning to maintain their appearance and corrosion resistance. For architectural applications, routine cleaning removes dirt and deposits that can trap moisture and corrosives against the surface. For a building in a clean, rural environment, normal rainfall may be sufficient. In urban or industrial areas, more frequent washing is needed.

The cleaning method should be as gentle as possible. For routine dirt, a simple wash with soap or a mild detergent and warm water, followed by a clean water rinse and wipe-dry, is usually sufficient. It's best to rub in the direction of the polish lines. For more stubborn stains or light rust, specialized stainless steel cleaners can be used. It is critical to avoid harsh abrasives like steel wool or scouring powders, as these will scratch the surface. Also, cleaners containing chlorides (especially bleach) must never be used, as they can cause severe pitting and staining.

A case in point is a hotel we supplied with 316 railings for their seaside pool area. We provided them with a simple maintenance schedule: a weekly freshwater rinse to wash off chlorine and salt deposits, and a monthly wash with a mild detergent. By following this simple, low-cost plan, the railings have remained bright and corrosion-free for years. In contrast, a nearby property that neglected this simple maintenance saw their railings develop brown staining within a year. This demonstrates that a small, proactive effort in maintenance is the key to unlocking the full, long-term value of a stainless steel investment.

| Consideration | Best Practice | Обоснование | Common Mistake |

|---|---|---|---|

| Lifting | Use padded slings, protected C-hooks | Prevents scratches and surface damage | Using carbon steel chains or hooks |

| Хранение | Store indoors, dry, off the ground | Prevents moisture and contamination | Storing outdoors, direct ground contact |

| Fabrication | Use dedicated stainless-only tools | Avoids iron cross-contamination | Using tools shared with carbon steel |

| Cleaning | Mild detergent, soft cloths, freshwater rinse | Preserves passive layer, prevents scratches | Using chloride bleach or steel wool |

Stainless steel requires proper lifting equipmentПравда

Using padded slings or protected C-hooks prevents surface damage and iron contamination that can lead to rust.

Stainless steel is maintenance-freeЛожь

While low-maintenance, all stainless steel grades require periodic cleaning to maintain corrosion resistance and appearance.

Заключение

Choosing the right stainless steel—304, 316, 201, or 430—is a strategic decision. By evaluating the environment, fabrication needs, and total lifecycle cost, not just the initial price, you ensure optimal performance, durability, and long-term value for your projects, building a truly resilient supply chain.

-

Understand the cost and performance trade-offs between grades 316 and 430 ↩

-

Understand why Grade 430's magnetic nature and low cost make it ideal for kitchen applications. ↩

-

Understand the challenges in welding grade 430 and necessary treatments to ensure durability ↩

-

Discover how molybdenum strengthens grade 316 against pitting in corrosive environments ↩

-

Explore the impact of nickel content on grade 201's suitability for different environments ↩

-

Learn techniques to minimize work hardening effects during stainless steel fabrication ↩

-

Evaluate the economic benefits of analyzing lifecycle costs versus initial purchase price ↩

-

Discover the typical uses for various stainless steel grades. ↩

-

Learn the cost-effective applications of 201 and 430 grades. ↩

-

Understand 316L's advantages in preventing leaks and corrosion. ↩

-

Learn how to prevent contamination and damage to stainless steel coils ↩

-

Find out how to maintain and clean 430 stainless steel surfaces ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.