304 Stainless Steel Identification: Quick Tests & Expert Tips

Struggling to confirm if your material is genuine 304 stainless steel? Misidentification leads to costly production failures and damages your reputation. Use these quick tests and expert tips to verify your material.

To identify 304 stainless steel, combine a visual inspection for finish and markings with a magnetic test (304 is typically non-magnetic). For definitive proof, use a chemical spot test or a portable XRF spectrometer for precise elemental analysis.

In my role as Global Business Director at MFY, I’ve seen firsthand how critical material accuracy is. A simple mix-up between grades can compromise a project's integrity, leading to significant financial losses. That's why having a reliable identification process is not just good practice; it's essential for business survival. I want to walk you through the practical, step-by-step methods our team uses to ensure quality, from the factory floor right to our clients' facilities. Let's dive in.

What Should You Look for in a Visual Inspection for 304 Stainless Steel?

Is that a surface defect or a sign of the wrong grade? Visual cues can be confusing. A trained eye, however, can spot initial clues, saving you valuable time.

During a visual inspection, look for a uniform, smooth surface finish, often labeled "2B" or "BA." Check for grade markings like "304" or "1.4301" stamped or etched onto the material, which provide the first clue to its identity.

A visual check is always our first line of defense. It's fast, requires no special equipment, and can immediately raise red flags. While it's not a definitive test, it’s a crucial part of the overall verification process. At MFY, we train our quality inspectors to look for specific indicators that help them make a preliminary assessment. This ability to quickly screen materials is a key part of maintaining operational efficiency, but we always stress that it's just the beginning of the story.

Key Visual Indicators

The most obvious starting point is the material's surface. A standard 304 stainless steel sheet often comes with a "2B" finish, which is smooth and moderately reflective. A "BA" or Bright Annealed finish will be much more mirror-like. You should also look for any markings from the mill. Manufacturers often stamp or laser-etch the grade ("304"), the heat number, and their logo directly onto the sheet or coil. The absence of any markings is an immediate cause for suspicion.

Limitations of Visual Checks

However, relying solely on what you see is a significant risk. Markings can be fraudulent, and different grades can have identical surface finishes. I remember a case with a new client who received a shipment from another supplier that looked perfect but failed in fabrication. The material was marked as 304 but was actually a lower-grade 200-series steel. This highlights the core challenge for quality professionals: visual checks are fast but cannot mitigate the risk of material misclassification, which can lead to catastrophic failures.

Why is a Magnetic Test a Crucial Step for Differentiating Stainless Steel Types?

A simple magnet can cause so much confusion. Some stainless steels are magnetic, others aren't. Understanding this difference is a quick, cost-free way to narrow down the possibilities immediately.

A magnetic test is vital because austenitic stainless steels like 304 are non-magnetic in their annealed state. If a strong magnet doesn't stick, it's a good indicator you may have 304, unlike magnetic ferritic grades like 430.

The magnetic test is one of the most practical field tests available. The crystal structure of 304 stainless steel is austenitic, which makes it non-magnetic when it leaves the mill in its annealed condition. This provides a clear point of differentiation from ferritic (like 430) or martensitic (like 410) stainless steels, which are all strongly magnetic. However, there's a critical detail that often trips people up.

The Cold-Working Exception

When 304 stainless steel is bent, stamped, or formed—a process known as cold working[^1]—its microstructure can change slightly, creating small amounts of martensite. This can induce a weak magnetic response. I once had a fabricator in India call me, concerned that a batch of our 304 pipes was magnetic. After a brief discussion, we realized the magnetism was only present at the bends where the pipe had been shaped. The straight sections were completely non-magnetic. This is a perfect example of why context is so important. A slight magnetic pull doesn't automatically disqualify the material, but it does mean you need to proceed to the next step for confirmation.

Quick Magnetic Comparison

| Steel Grade | Family | Typical Magnetic Response |

|---|---|---|

| 304 | Austenitic | Non-magnetic (can become slightly magnetic after cold work) |

| 316 | Austenitic | Non-magnetic (less susceptible to magnetism from cold work than 304) |

| 430 | Ferritic | Магнит |

| 410 | Martensitic | Магнит |

How Can Chemical Analysis Provide Accurate Identification of 304 Stainless Steel?

Visual and magnetic tests aren't enough for critical applications. You need certainty. Chemical analysis provides definitive proof of your material's composition, eliminating all guesswork and risk.

Chemical analysis confirms 304 stainless steel by verifying its elemental composition, primarily 18% chromium and 8% nickel. This can be done with simple spot test kits or, for higher accuracy, with portable X-ray fluorescence (XRF) analyzers.

When there's no room for error, we move to chemical analysis. This is where we get a definitive answer. The identity of 304 stainless steel is rooted in its chemistry: roughly 18% chromium and 8% nickel. Verifying these percentages is the only way to be 100% certain. For years, the industry relied on chemical spot test kits. These kits use acids to produce a color reaction that indicates the presence of certain elements, like nickel. They are a cost-effective method but can be messy and require a skilled operator to interpret the results correctly.

The Rise of Portable Technology

Today, the industry trend is moving towards faster, more precise, and non-destructive methods. This is where technology like handheld X-ray fluorescence (XRF) analyzers comes in. At MFY, our quality teams are equipped with these devices. They can provide a complete elemental breakdown of the material in seconds without damaging the surface. This technology is a game-changer because it perfectly balances speed with accuracy, directly addressing the core need of manufacturers and inspectors. Adopting these tools helps us mitigate the risk of misclassification, preventing the kind of costly production errors that can harm a company's reputation. It aligns with the broader industry push towards digitalization and higher quality standards, giving us and our clients a real competitive edge.

What are the Expert Tips for Confirming 304 Stainless Steel?

The tests are done, but you still feel uncertain. What do seasoned professionals do? These expert tips go beyond the basics, giving you the confidence to make the final call.

Experts always cross-reference test results with the Material Test Certificate (MTC). They also consider the material's intended application and trust, but always verify, information from their suppliers. When in doubt, send a sample to a lab.

Over my years in this business, I've learned that testing is only one part of the equation. True quality assurance comes from a holistic approach that combines data, documentation, and partnership. A test result is just a number until it's placed in the proper context. That’s why we always tell our clients that the best way to guarantee material quality is to build a process around verification, not just a single test.

Always Demand the MTC

The Material Test Certificate (MTC) or Mill Test Report (MTR) is the material's birth certificate. It is a quality assurance document provided by the mill that details the exact chemical composition and mechanical properties of that specific batch of steel. We always cross-reference the heat number on the MTC with the number stamped on the material itself. If they don't match, or if a supplier can't provide an MTC, it's a major red flag.

Trust, But Verify

I remember a client in Germany who almost rejected a large shipment of 304 coils because a magnet showed a slight pull at the edges. They were worried they had received the wrong grade. We immediately sent them the MTC for that heat number, explained the cold-working effect from the slitting process, and encouraged them to perform a chemical spot test. The test confirmed the nickel content was correct. This experience reinforced a core principle: even with trusted partners, you must have a verification process. It protects everyone and builds stronger, more transparent relationships.

What are the Common Mistakes to Avoid in Stainless Steel Identification?

A small mistake can have big consequences. Avoiding common identification pitfalls is crucial. Knowing what not to do is just as important as knowing what to do for quality assurance.

The most common mistakes are relying on a single test (especially visual or magnetic), ignoring the effects of cold working on magnetism, and failing to request or verify the Material Test Certificate (MTC) from the supplier.

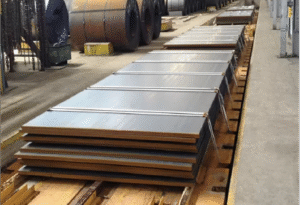

Stacks of high-quality stainless steel coils in a warehouse, ready for distribution by MFY China.](https://cnmfy.com/wp-content/uploads/2025/08/high-quality-stainless-steel-coils-2.webp)

Ensuring you have the right material is about having a robust process. Where I see most people go wrong is by taking shortcuts. They rely on one test or one piece of information and make a call, which opens them up to significant risk. The cost of misclassification isn't just the price of the material; it's the wasted labor, the project delays, and the potential damage to your reputation. To protect your operations, you must be aware of these common pitfalls and actively work to avoid them.

Mistake 1: Relying Only on Magnetism

As we discussed, the magnetic test is a great initial indicator, but it's not foolproof. The cold-working effect can create false negatives (or positives, depending on your perspective). Furthermore, other non-magnetic grades exist. Relying solely on a magnet is one of the fastest ways to make a costly error.

Mistake 2: Ignoring Documentation

Some procurement specialists focus only on price and delivery time, overlooking the MTC. This document is your only link back to the source and your ultimate proof of quality. A supplier who is hesitant to provide full documentation should not be trusted.

Mistake 3: Confusing Surface Finish with Quality

A shiny, clean surface looks great, but it says nothing about the underlying chemical composition of the steel. Fraudulent suppliers are experts at making low-grade material look like high-quality 304. Never let the appearance of the material override the need for proper testing and documentation.

| Mistake | Consequence | How to Avoid |

|---|---|---|

| Relying on a single test | High risk of misclassification | Use a multi-step process: visual, magnetic, and chemical tests. |

| Ignoring the MTC | No proof of origin or quality; no recourse if material fails | Always demand the MTC and verify the heat number matches the material. |

| Forgetting cold work | Misinterpreting a slightly magnetic 304 as the wrong grade | Understand that forming can induce magnetism; use a chemical test for confirmation. |

Заключение

Accurate 304 identification isn't about a single magic test. It's a systematic process: combining quick checks like visual and magnetic tests with definitive chemical analysis and proper documentation. This multi-layered approach ensures quality, prevents costly errors, and ultimately protects your bottom line.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.