Industrial-Scale Rust Remediation for Stainless Steel Coils and Pipes

Seeing rust on your "stainless" steel is alarming. It compromises integrity and project timelines. Understanding its causes and modern remedies protects your investment and ensures long-term performance.

The best approach combines proactive prevention with advanced remediation. This involves selecting the right grade, controlling environmental factors, and using modern, eco-friendly techniques like automated surface restoration to maintain material integrity, performance, and value.

Let's break this down. As someone who has managed global stainless steel supply chains for years at MFY, I've seen how a small spot of rust can become a massive operational headache. It’s a topic that seems simple on the surface but has deep implications for project success and profitability. It's a conversation that deserves a closer look.

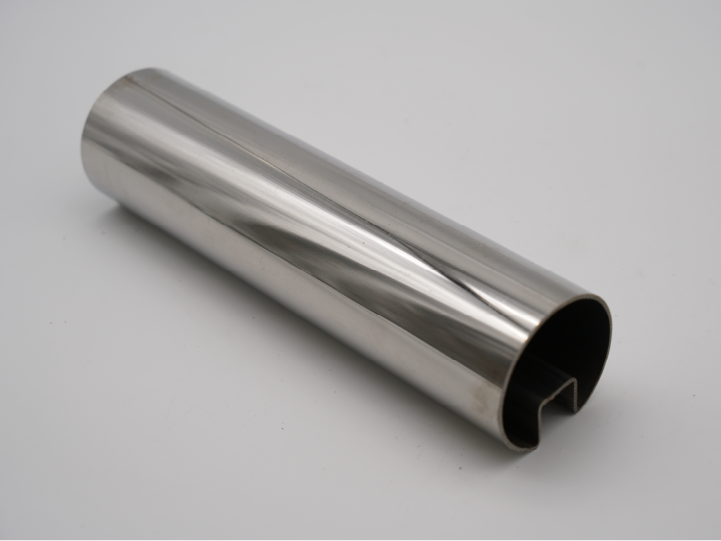

What are the common causes of rust in industrial-scale stainless steel coils and pipes?

You expect stainless steel to be rust-proof. But contamination, chlorides, and poor handling can cause unexpected corrosion. Identifying these triggers is the first step to effective prevention.

Common causes include contamination from carbon steel particles, exposure to aggressive chloride environments (like coastal air or de-icing salts), improper handling that damages the passive layer, and selecting the wrong steel grade for the application.

The term "stainless" steel is a bit of a misnomer; it's more accurate to call it "corrosion-resistant" steel. Its resistance comes from a microscopic, invisible layer of chromium oxide on its surface, known as the passive layer. When this layer is damaged or compromised, rust can form. I remember a client in Southeast Asia who was building a coastal processing plant. They used grade 304 for exterior pipe racks, assuming it was sufficient. Within a year, they saw significant surface rust. The problem wasn't the quality of the steel; it was a mismatch between the grade and the high-chloride, salt-spray environment. This is a classic example of why understanding the root cause is so critical.

Key Factors in Corrosion

The passive layer can be compromised in several ways. The most common culprit in industrial settings is contamination. If tools used for carbon steel, like grinders, brushes, or lifting chains, are then used on stainless steel, they can leave behind tiny iron particles. These particles rust, and this rust can break down the passive layer and initiate corrosion on the stainless steel itself. This is why dedicated, "stainless-only" fabrication areas are a best practice. Environmental factors are the other major cause.

Environmental and Grade-Related Causes

Chlorides are the primary enemy of stainless steel. They are found in coastal air, de-icing salts, and even in some industrial chemicals and cleaning agents. When chlorides concentrate on the surface, they can chemically attack and penetrate the passive layer, leading to pitting corrosion[^1]. This is why for marine or chemical environments, a higher-grade material like 316, which contains molybdenum for enhanced chloride resistance, is essential.

| Cause | Description | Risk Level |

|---|---|---|

| Iron Contamination | Particles from carbon steel tools or structures embed in the surface. | High |

| Chloride Exposure | Salt from coastal air, de-icing salts, or chemicals attack the passive layer. | High |

| Improper Handling | Scratches, gouges, or heat from welding can damage the passive layer. | Medium |

| Wrong Grade Selection | Using a grade (e.g., 304) in an environment requiring a higher grade (e.g., 316). | Very High |

How does rust impact the performance and longevity of stainless steel products?

A little rust seems purely cosmetic. But it can quickly lead to structural failure, product contamination, and costly replacements. Understanding its true impact highlights the need for immediate action.

Rust compromises stainless steel's structural integrity through pitting and crevice corrosion, reducing its load-bearing capacity. It also degrades surface finish, poses contamination risks in sanitary applications, and significantly shortens the product's operational lifespan.

The impact of rust goes far beyond aesthetics; it strikes at the core of why you chose stainless steel in the first place—its durability and reliability. For our clients in the manufacturing and construction sectors, asset longevity is directly tied to profitability. When rust appears, it's not just a surface problem; it's a warning sign of deeper issues that can have severe financial and operational consequences. The global demand for higher quality assurance, which we see every day at MFY, is driven by a desire to avoid these very consequences. Ignoring rust is equivalent to ignoring a critical failure alert in your operations.

Structural Integrity and Safety

The most dangerous impact of rust is its effect on structural integrity. Pitting corrosion, which appears as small, deep pits, can penetrate the material's thickness, severely weakening it from the inside out. For a high-pressure pipe or a load-bearing structural component, this can lead to catastrophic failure without much external warning. This is a massive safety risk and a liability that no company can afford. Crevice corrosion, which occurs in tight spaces like under gaskets or bolt heads, can be equally insidious. It's a silent threat that undermines the reliability of entire systems.

Financial and Operational Consequences

From a business perspective, the costs are substantial. First, there's the direct cost of replacement, including material, labor, and equipment. Then there are the indirect costs of operational downtime, which for a manufacturing plant or a power station can run into millions per day. Furthermore, in industries like food processing or pharmaceuticals, any rust presents a contamination risk that can lead to product spoilage, recalls, and severe damage to a brand's reputation. This is why forward-thinking companies are shifting their focus from reactive repair to proactive maintenance and investing in supply chains that guarantee material integrity from the start.

What industrial techniques are available for effective rust remediation of stainless steel?

You've found rust, now what? Traditional methods can be slow, costly, and harsh on the material itself. Modern industrial techniques, however, offer far more efficient, safe, and effective solutions.

Effective techniques range from mechanical methods like abrasive blasting to chemical treatments using pickling and passivation acids. Increasingly, advanced options like laser cleaning and automated surface restoration offer precise, eco-friendly, and highly efficient remediation.

The field of rust remediation is evolving rapidly. For decades, the standard approach was aggressive and often manual—think wire brushes, grinders, and harsh pickling pastes. While effective, these methods can be labor-intensive, create safety hazards, and even alter the surface finish of the steel. Today, the industry is demanding smarter, faster, and more sustainable solutions. This is where the core of my insight lies: the future of remediation is in advanced, scalable technologies. At MFY, we are constantly exploring partnerships with tech innovators because we see this as a critical value-add for our clients. They don't just want steel; they want a guarantee of performance, and that includes having a plan for remediation.

The Shift to Advanced Technologies

Eco-friendly chemical treatments are replacing older, more hazardous acids. These new formulations are just as effective at removing rust and restoring the passive layer but are safer for workers and have a lower environmental impact. Even more exciting is the rise of automated and robotic surface restoration. Laser cleaning, for example, uses a focused beam of light to vaporize rust and contaminants from the surface without touching or abrading the steel itself. It's incredibly precise, fast, and produces minimal waste. These technologies are no longer science fiction; they are becoming practical, cost-effective solutions for large-scale operations.

Comparing Remediation Methods

Investing in these technologies is a strategic move. It reduces downtime, lowers labor costs, ensures a consistent, high-quality finish, and aligns with corporate sustainability goals. This is the revolution happening in metal maintenance.

| Technique | Pros | Cons | Best For |

|---|---|---|---|

| Mechanical (Grinding) | Fast for heavy rust. | Can damage surface; requires re-passivation. | Heavy, localized corrosion. |

| Chemical (Pickling) | Restores passive layer. | Uses hazardous acids; requires careful handling. | Widespread surface rust, post-welding. |

| Laser Cleaning | Highly precise; no abrasives; eco-friendly. | High initial equipment cost. | High-value components; sensitive surfaces. |

| Automated Blasting | Consistent finish; scalable. | Requires contained environment. | Large coils, long pipes, new fabrication. |

How can industries prevent rust formation in stainless steel coils and pipes?

Remediation is a costly cure. Constantly fighting rust drains resources and causes operational delays. Proactive prevention is always the most effective and economical strategy for long-term material integrity.

Rust prevention involves selecting the correct stainless steel grade for the environment, ensuring proper handling and storage to avoid contamination, maintaining the protective passive layer, and implementing regular cleaning and inspection schedules.

I can't stress this enough: the battle against rust is won or lost long before the material is even installed. It begins with the initial specification and continues through every step of the supply chain. At MFY, our integrated model gives us a unique advantage because we can control quality and handling from the mill to the port to the final delivery. We've seen firsthand how a small lapse in storage protocol—like storing stainless steel coils next to carbon steel—can lead to widespread contamination that costs a fortune to fix later. Prevention is about diligence and process control.

Material Selection and Design

The first line of defense is choosing the right material. This goes back to my earlier story about the coastal plant. A thorough analysis of the service environment—considering temperature, humidity, and chemical exposure (especially chlorides)—is non-negotiable. Using a corrosion resistance calculator or consulting with a materials expert can save you from a costly mistake. For example, grade 316[^2]L is our standard recommendation for any marine or coastal application, as the added molybdenum provides crucial protection against chloride pitting. Design also plays a role. Designing components to avoid crevices and allow for water drainage can significantly reduce the risk of localized corrosion.

Supply Chain and Handling Protocols

Once the right material is selected, it must be protected. This means enforcing strict handling protocols. Use dedicated lifting straps, nylon separators, and protective films. Store stainless steel indoors in a dry, clean environment, and never allow it to come into contact with carbon steel. This includes tools, workbenches, and storage racks. A well-managed supply chain partner will have these protocols deeply embedded in their operations. It’s a key indicator of a supplier's commitment to quality and a core part of our promise to our customers. This focus on prevention is not just good practice; it’s a pillar of sustainable operations, reducing waste and the need for costly, resource-intensive remediation down the line.

What are the best practices for maintaining rust-free stainless steel products in industrial settings?

Your stainless steel is installed and operational. But neglect can quickly undo all your careful planning and investment. A simple, consistent maintenance routine is the key to ensuring lifelong performance and appearance.

Best practices include regular cleaning with appropriate neutral cleaners, periodic inspection for early signs of corrosion, immediate removal of any contaminants, and re-passivation of any areas that have been scratched or mechanically altered during use.

Think of stainless steel maintenance like caring for a high-performance vehicle. You wouldn't skip oil changes and expect it to run forever. Similarly, stainless steel requires a basic level of attention to deliver the multi-decade lifespan it's capable of. The good news is that the required maintenance is straightforward and not overly burdensome. The key is consistency. Establishing a simple maintenance schedule and training your staff on the correct procedures is one of the highest-return investments you can make in the longevity of your facility. It transforms stainless steel from a passive material into a actively managed asset.

Developing a Maintenance Program

A robust maintenance program is built on inspection and cleaning. The frequency depends on the environment. In a clean, interior setting, an annual inspection might suffice. In a harsh, coastal, or industrial environment, monthly or even weekly checks are wiser. Staff should be trained to look for any signs of discoloration, deposits, or light staining, as these are the earliest indicators of potential trouble. For cleaning, the rule is to start with the gentlest method possible. Often, warm water and a mild detergent applied with a soft cloth or sponge are all that's needed.

A Practical Maintenance Checklist

It's crucial to avoid using harsh or improper cleaning tools. Steel wool, carbon steel brushes, and chlorine-based cleaners (like bleach) should never be used on stainless steel, as they will cause rusting. Here is a simple framework for a maintenance schedule:

| Frequency | Action | Tools/Materials |

|---|---|---|

| As Needed | Spot clean spills, deposits, or fingerprints. | Soft cloth, mild soap and water. |

| Monthly | Visually inspect all surfaces, especially crevices and welds. | Flashlight, inspection mirror. |

| Quarterly/Bi-Annually | Perform a routine wash-down of all exposed surfaces. | Low-pressure hose, neutral detergent. |

| Annually | Conduct a thorough inspection for any scratches or damage. | Full inspection kit. Re-passivate any repaired areas. |

By adopting these practices, you move from a reactive to a proactive stance, ensuring your stainless steel assets remain truly "stainless" for their entire service life.

Conclusion

Protecting your stainless steel investment is about more than just buying the right material. It requires a lifecycle approach—from proactive prevention and smart selection to leveraging advanced, sustainable remediation when needed. This holistic strategy is what ensures longevity, performance, and a truly resilient supply chain.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.