Stainless Steel Sheet Manufacturing Process: From Hot Slab to Cold-Rolled Precision

Struggling to grasp the complex journey from a raw slab of steel to a flawless, finished sheet? This knowledge gap can lead to costly errors in material specification, causing project delays and budget overruns. Let me guide you through the intricate manufacturing process we at MFY have perfected.

The stainless steel sheet manufacturing process begins with reheating a thick, semi-finished slab of steel1 in a furnace to a malleable temperature, typically above 1,100°C. This is immediately followed by high-pressure water descaling2 to remove any surface impurities, ensuring a clean slate for subsequent shaping and rolling.

As the Global Business Director for MFY, I’ve seen firsthand how a deeper understanding of this process empowers our clients, from engineering contractors in Southeast Asia to equipment integrators in the Middle East. It transforms the procurement conversation from one based solely on price to one focused on value, performance, and achieving the perfect material specification for the application. This journey from fiery slab to precision sheet is a testament to engineering excellence.

This transformation is a multi-stage marathon of heat, pressure, and meticulous refinement. It’s where raw strength is molded into engineered elegance. The initial steps are foundational, setting the stage for the quality of the final product. Understanding how a simple slab is prepared for its journey is crucial for appreciating the precision that follows. We'll delve into how this raw potential is unlocked through controlled heating and aggressive cleaning, ensuring the final product meets the highest standards of quality and performance, a non-negotiable for our clients' demanding applications.

What are the initial steps in transforming a hot slab into a stainless steel sheet?

Ever wondered how a massive, glowing slab of steel begins its journey to becoming a precise, high-performance sheet? It’s a process where immense heat and force are applied with incredible control. Getting these first steps wrong can compromise the entire batch, leading to defects and performance failures.

The initial steps involve taking a continuously cast stainless steel slab and reheating it uniformly in a walking-beam furnace to over 1,100°C (2,012°F)3. This is followed by a high-pressure descaling process, where water jets blast away the oxidized surface layer, ensuring a clean, defect-free material.

With the slab now uniformly heated and its surface pristine, it's prepared for the first major shaping phase. This isn't just about making it thinner; it's about fundamentally altering its internal structure. The next stage, hot rolling, is where brute force meets metallurgical science. It's a dynamic, high-impact process that dramatically reduces the slab's thickness and begins to define the sheet's initial mechanical properties. As we move from preparation to transformation, you'll see how each roaring pass through the rollers is a calculated step towards the final product's intended strength and dimensions. I’ve often explained to our manufacturing clients in India that understanding this stage is key to appreciating why consistent thickness and grain structure are so vital. It’s the foundation upon which all subsequent precision work, including cold rolling and finishing, is built. Without a perfectly executed hot rolling process, achieving the fine tolerances and flawless surfaces required for high-end applications would be impossible. This is where MFY’s commitment to integrated, quality-controlled production truly begins to shine, ensuring that the journey from slab to coil starts on solid ground.

The initial preparation of a stainless steel slab is arguably one of the most critical phases in the entire manufacturing chain, directly influencing the final product's surface quality, structural integrity, and performance. At MFY, we view this not as a preliminary step but as the fundamental groundwork for excellence. This stage is more than just heating and cleaning; it's about setting a flawless baseline. Any shortcuts or inconsistencies here, such as non-uniform heating or incomplete scale removal, will be magnified in subsequent processes, leading to defects that are often impossible to correct later. This is why our investment in state-of-the-art furnace technology and high-pressure descaling systems is non-negotiable. It ensures that every slab entering our rolling mills is in an optimal state for transformation. The goal is to create a homogenous, clean, and malleable piece of steel, ready for the immense pressures and precise shaping that lie ahead, guaranteeing the quality our global clients have come to expect.

The Science of Reheating: Achieving Uniform Malleability

The journey begins in a reheating furnace, typically a walking-beam type, where slabs are heated to a precise temperature, usually between 1,150°C and 1,250°C4. The goal here is not just to make the steel hot, but to achieve a perfectly uniform temperature throughout the slab's entire volume. This uniformity is critical for ensuring consistent plastic deformation during hot rolling. A study by the Association for Iron & Steel Technology (AIST) indicates that a temperature deviation of as little as 20°C across the slab can result in thickness variations and internal stresses in the final sheet.

I recall a case with a new engineering client in Russia who was experiencing inconsistent forming behavior with sheets from a previous supplier. Upon analysis, we traced the issue back to improper reheating practices. Slabs were not "soaked" at the target temperature for long enough, leading to a cooler core. When rolled, this resulted in a heterogeneous grain structure, causing unpredictable behavior during their fabrication processes. At MFY, our process control software meticulously monitors slab temperature at multiple points, adjusting furnace zones in real-time to ensure every slab achieves complete and uniform thermal saturation before proceeding.

This process is a delicate balance. Overheating can lead to excessive grain growth and scale formation, which degrades the material properties and yield. Underheating results in higher resistance to deformation, putting immense strain on the rolling mill and potentially causing surface fractures. Our automated systems, calibrated against years of production data, ensure we hit that perfect thermal sweet spot for each specific grade of stainless steel, from standard 304 to more demanding alloys. This precision in the heating phase is the first guarantee of quality in our integrated supply chain.

The Critical Role of High-Pressure Descaling

As the slab exits the furnace, it's covered in a layer of iron oxide, or "scale." If not removed, this brittle layer would be pressed into the steel surface during rolling, creating severe defects like pitting and inclusions. The descaling process uses high-pressure water jets, often operating at pressures exceeding 200 bar (2,900 psi)5, to blast this scale off the surface. The immense thermal shock caused by the water hitting the red-hot steel, combined with the mechanical force of the jets, effectively shatters and removes the oxide layer.

The effectiveness of descaling is a direct function of pressure, volume, and nozzle configuration. We recently upgraded our descaling boxes with optimized nozzle patterns based on fluid dynamics simulations. This change increased scale removal efficiency by over 15%, according to our internal quality metrics, and has been particularly beneficial for producing high-gloss, mirror-finish sheets. For a distributor in the Middle East who supplies to architectural projects, the flawless surface finish is a key selling point. Our enhanced descaling process ensures we can deliver on this promise consistently.

Inadequate descaling is a common source of quality issues in the industry. I have seen competitors' products with "rolled-in scale," which appears as dark, embedded streaks or patches, rendering the sheet unusable for aesthetic or sanitary applications. Our multi-stage descaling system—with units placed before the first rolling stand and between subsequent passes—is a core part of our quality assurance. It ensures that the surface we are working with is pristine at every critical juncture of the hot rolling process. This relentless focus on a clean surface is fundamental to MFY's reputation for producing superior quality stainless steel sheets.

From Slab to Billet: Initial Shaping and its Impact on Quality

After descaling, the slab makes its first passes through a "roughing mill." This is where the initial, significant reduction in thickness occurs. The slab is passed back and forth through a set of massive rollers that squeeze it, elongating it and reducing its cross-sectional area. This initial shaping is not just about size reduction; it's about breaking down the coarse, as-cast grain structure of the slab. This process, known as grain refinement, is crucial for improving the steel's mechanical properties, such as toughness and ductility.

The reduction per pass is carefully calculated. According to industry data, an optimal reduction schedule in the roughing phase can improve the final sheet's toughness by up to 25% compared to an overly aggressive or conservative schedule. Our process models dictate the precise roll gap and speed for each pass, tailored to the specific grade and target properties. For instance, when producing sheets for a major manufacturing client who makes high-pressure vessels, ensuring a fine, homogenous grain structure from the roughing mill is paramount for the final product's safety and reliability.

This stage effectively transforms the raw slab into a "transfer bar" or billet, a long, thinner piece of steel ready for the final hot rolling stands. The consistency of the billet's width, thickness, and temperature profile is a direct predictor of the final hot-rolled coil's quality. Our integrated approach means the data from the reheating furnace and descalers is fed forward to the roughing mill controls. This ensures that any minor variations are compensated for in real-time, delivering a highly consistent billet to the next stage and embodying MFY’s principle of continuous, data-driven improvement across our entire production line.

Slabs are heated above 1,100°CTrue

The article states slabs are reheated to typically above 1,100°C to achieve proper malleability for rolling.

Descaling uses low-pressure waterFalse

High-pressure water jets exceeding 200 bar (2,900 psi) are used for effective scale removal, not low-pressure water.

How does the hot rolling process shape the stainless steel slab into sheets?

Your project demands strong, reliable stainless steel, but have you considered how its fundamental properties are forged? The hot rolling process is where raw steel is shaped and its core metallurgical DNA is defined. A flawed process here can lead to internal defects and inconsistent performance.

Hot rolling6 shapes the stainless steel by passing the reheated slab through a series of synchronized rollers, called a finishing mill, at high speed. This progressively reduces the slab's thickness to the target dimension, elongates it, and refines its grain structure, imparting essential mechanical properties.

Emerging from the hot rolling mill, we have a coil of stainless steel that has its basic shape and mechanical properties. However, it's a product born of extreme heat and force. The internal stresses are high, and the grain structure, while refined, is hardened and not yet optimal for many applications, especially those requiring forming or deep drawing. The surface is covered in a dark oxide layer, far from the clean, bright finish many associate with stainless steel. This is where the process must pivot from brute force to finessed refinement. To unlock the material's full potential for ductility and workability, and to prepare it for its final, pristine surface finish, it must undergo a crucial heat treatment process. This next step, annealing7, is what relieves the internal stresses and recrystallizes the grain structure, making the steel softer and more formable. It’s a critical bridge between the hot-formed shape and the cold-rolled precision that comes later. Without it, the material would be too brittle for further processing or for our customers' fabrication needs.

The hot rolling stage is a spectacular display of industrial might, a high-speed, high-temperature process that is foundational to the final characteristics of the stainless steel sheet. At MFY, we see this not merely as a size-reduction step, but as a critical phase of material engineering. Here, the reheated and descaled slab, now a transfer bar, is fed into a tandem finishing mill—a series of 6 to 7 rolling stands operating in perfect synchrony. The bar enters the first stand at speeds of around 1 meter per second and exits the last stand as a thin strip traveling at up to 20 meters per second, all while its temperature is carefully controlled. This process doesn't just make the steel thinner; it fundamentally reorients and refines its crystalline structure. The combination of intense pressure and controlled temperature dictates the material's final strength, toughness, and formability. This is why our process control systems are so advanced, ensuring that every meter of the coil has a consistent microstructure and uniform mechanical properties, a critical requirement for clients in demanding sectors like automotive manufacturing and heavy construction.

The Tandem Mill: A Symphony of Speed and Pressure

The heart of the hot rolling process is the finishing mill, a sequence of rolling stands that the steel passes through once in a continuous process. Each subsequent stand has a smaller roll gap and runs at a higher speed than the one before it. This precise synchronization is essential to maintain tension in the strip and prevent it from buckling or tearing. The total reduction in thickness from the transfer bar to the final hot-rolled coil can be over 90%, achieved in a matter of seconds. For example, a 30mm thick transfer bar can be rolled down to a 2.5mm thick strip.

The forces involved are immense, with rolling forces on each stand reaching up to 4,000 tons. Sophisticated Automatic Gauge Control (AGC)8 systems use hydraulic actuators to adjust the roll gaps thousands of times per second, ensuring the thickness is uniform along the entire length of the coil. I've personally reviewed the data logs for a production run for a construction contractor in Southeast Asia who required thousands of tons of sheet for structural components. Our AGC systems maintained a thickness tolerance of ±0.05mm over hundreds of coils, a level of consistency that was critical for the project's automated welding and assembly lines.

This level of precision is not just about meeting specifications; it's about providing our customers with a predictable, reliable material that optimizes their own processes. Inconsistent thickness can lead to problems in stamping, forming, and welding, causing downtime and scrap. By investing in and meticulously maintaining our tandem mill's control systems, we provide a product that performs consistently, reflecting MFY’s commitment to being a reliable partner in our clients' success.

Thermomechanical Processing: Engineering the Microstructure

Hot rolling is a classic example of thermomechanical processing. It's not just a mechanical shaping process; the "thermo" aspect is just as important. The rolling is performed within a specific temperature range, typically finishing between 850°C and 950°C for austenitic stainless steels like 304 or 316. This finishing temperature is critical because it determines the final grain size and the extent of recrystallization—the process where deformed grains are replaced by new, stress-free ones. A finer grain size generally results in higher strength and better toughness.

We engineer the microstructure for specific applications. For example, a client manufacturing industrial-grade kitchen equipment needs a material that is highly formable (for deep drawing sinks) but also strong. By precisely controlling the finish rolling temperature and the subsequent cooling rate on the run-out table, we can optimize the grain structure to provide this ideal balance of ductility and strength. Research published in metallurgical journals consistently shows that a 10°C change in the finish rolling temperature can alter the final yield strength by as much as 5-10 MPa.

This ability to tailor properties is a key competitive advantage for MFY. While many see hot rolling as a bulk process, we approach it as a precision engineering step. We work with our customers, like equipment integrators, to understand their fabrication challenges and tune our hot rolling parameters accordingly. This deep integration of material science and practical application is how we deliver more than just a commodity product; we deliver a targeted solution.

Cooling, Coiling, and Quality Control on the Run-Out Table

As the now-thin strip of steel exits the final finishing stand at high speed, it travels along a long platform called the run-out table. This is where the final, critical cooling phase occurs before the strip is coiled. Banks of water spray nozzles are positioned above and below the strip, and they are used to control the cooling rate with extreme precision. The rate at which the steel is cooled from its finish rolling temperature down to the coiling temperature (typically 550°C-650°C) has a profound impact on the final microstructure and the precipitation of various phases within the steel.

For certain grades, rapid cooling is essential to prevent the formation of undesirable precipitates at the grain boundaries, which could impair corrosion resistance. For others, a slower cooling rate is needed to achieve the desired mechanical properties. Our process control system modulates the water flow to hundreds of individual spray headers to achieve a specific, pre-programmed cooling profile. This dynamic control is essential. For instance, a client supplying pipes for the petrochemical industry requires a material with maximum corrosion resistance. For their orders, we employ a rapid cooling profile to ensure the chromium remains in solution, preventing sensitization and ensuring long-term durability in harsh environments.

ly, at the end of the run-out table, a massive downcoiler wraps the thousands of meters of steel strip into a tight coil. Even here, precision is key. The coiling tension must be carefully controlled to avoid damaging the strip or creating a loose, unstable coil. Laser-based sensors monitor the strip's profile and shape in real-time, feeding back data to ensure a high-quality, geometrically sound coil is produced. This hot-rolled coil, often called a "black coil" due to its dark, oxidized surface, is the primary output of this process and the input for the next stages of finishing.

Hot rolling reduces slab thicknessTrue

The hot rolling process progressively reduces the slab's thickness by passing it through synchronized rollers in the finishing mill.

Hot rolling creates final surface finishFalse

Hot rolling produces a dark oxide layer on the surface; final surface finishes are achieved through subsequent processes like annealing and cold rolling.

What role does annealing play in the stainless steel sheet production?

You've specified a stainless steel sheet for its strength, but your fabrication process requires it to be easily formed. The hardness from rolling can make it brittle and prone to cracking. This is where annealing becomes the crucial, property-defining step in manufacturing.

Annealing is a critical heat treatment process where the stainless steel is heated9 to a specific temperature (e.g., ~1040°C for 304 grade) and then rapidly cooled. This relieves internal stresses, softens the material by recrystallizing its grain structure, and enhances its ductility and corrosion resistance.

Now that the material has been annealed, it is metallurgically "reset." It is softer, more formable, and free from the internal stresses accumulated during hot rolling. The dark, rough scale from the hot-rolling and annealing processes, however, remains. While the internal structure is now optimized, the surface is far from ready for most applications. To achieve the bright, smooth, and precise finish that customers expect from stainless steel, the sheet must undergo another round of processing. The pickling and cold rolling process10 is crucial to achieve exceptional thickness tolerances, controlled surface finishes, and further increases in strength that define high-quality stainless steel sheets. It's the step that transforms a workable material into a high-performance, precision-engineered product, ready to meet the exacting standards of our clients.

After the intense pressures of hot rolling, the stainless steel coil possesses significant internal stresses and a work-hardened microstructure. In this state, it is too brittle for many forming operations and its corrosion resistance may be compromised. Annealing is the essential therapeutic step that resolves these issues. At MFY, we operate a continuous annealing and pickling (AP) line where the coil is unwound and passed through a furnace under controlled atmospheric conditions. This heat treatment process is not merely about heating and cooling; it is a precise metallurgical recalibration. It recrystallizes the deformed grain structure into a new set of equiaxed, stress-free grains. This transformation dramatically increases the material's ductility and formability, making it suitable for deep drawing, bending, and other complex fabrication tasks. It also re-dissolves certain carbide precipitates back into the steel matrix, which is vital for restoring the full corrosion resistance of the stainless steel, a primary reason our customers choose this material.

The Mechanism of Recrystallization and Stress Relief

Work hardening, which occurs during hot rolling, involves the entanglement and piling up of dislocations within the steel's crystal lattice. This is what makes the material harder and stronger, but also less ductile. Annealing provides the thermal energy needed for recovery and recrystallization. During the "soaking" period in the furnace at a specific annealing temperature (for example, around 1040°C for Type 304), new, strain-free grains nucleate and grow, consuming the old, deformed grains. The result is a complete renewal of the microstructure.

The precise control of annealing time and temperature is critical. Under-annealing will result in incomplete recrystallization, leaving the material harder and less formable than desired. Over-annealing can lead to excessive grain growth, which can degrade the material's strength and result in a rough "orange peel" surface texture after forming. I once worked with an equipment integrator whose previous supplier provided material that was cracking during a bending operation. Our lab analysis showed a partially annealed structure. By providing them with fully annealed sheets from our precisely controlled AP line, where pyrometers monitor the strip temperature in real-time, we eliminated the cracking issue, saving them significant costs in scrap and rework.

This process essentially resets the material's properties, creating a soft, ductile, and stress-relieved state. This blank slate is crucial because it ensures predictable and uniform behavior during our customers' subsequent fabrication processes. It’s a perfect example of MFY's philosophy: investing in process control to deliver a product our customers can trust.

Enhancing Corrosion Resistance Through Annealing

Beyond just softening the material, annealing plays a vital role in ensuring the hallmark corrosion resistance of stainless steel. During processing, particularly if cooling rates after hot rolling are not optimal, chromium carbides can precipitate at the grain boundaries. This process, known as sensitization, depletes the chromium in the area adjacent to the grain boundary, making these regions susceptible to intergranular corrosion. This can be a catastrophic failure mode in demanding environments, such as those encountered by our clients in the chemical processing or marine industries.

The annealing process heats the steel to a temperature high enough to dissolve these harmful chromium carbides back into the solid solution of the steel matrix. The subsequent rapid cooling (quenching), typically with water or forced air, "freezes" the chromium in solution, preventing it from precipitating again. This ensures a consistent level of chromium throughout the material, which is essential for the formation of the passive, corrosion-resistant oxide layer that protects the steel.

For a client providing components for desalination plants in the Middle East, ensuring complete resistance to chloride-induced corrosion is a matter of public safety and equipment longevity. Our HAPL (Horizontal Annealing and Pickling Line) is designed with a high-efficiency quenching section that reduces the strip temperature through the critical sensitization range (approx. 870°C to 425°C) in a matter of seconds. This technical capability allows us to guarantee the corrosion performance specified in international standards like ASTM A240, giving our clients the confidence to operate in the most aggressive environments.

The Symbiotic Relationship with Pickling

Annealing and pickling are almost always performed in a single, continuous line because they are intrinsically linked. The high temperatures of annealing create a new, thick layer of oxide scale on the steel's surface. This scale must be removed before any further processing, like cold rolling. Immediately after the coil is annealed and quenched, it passes into the pickling section of the line. Pickling involves immersing the steel strip in a series of tanks containing heated acids, typically a mixture of nitric and hydrofluoric acids.

This chemical process dissolves the oxide scale, revealing the clean, metallic surface of the stainless steel underneath. The efficiency of pickling is dependent on the nature of the scale formed during annealing. A well-controlled annealing process creates a scale that is more easily and uniformly removed. This synergy is why integrated Annealing and Pickling (AP) lines are the industry standard for quality production.

At MFY, our AP line uses advanced acid concentration and temperature controls, along with electrolytic assistance, to optimize the pickling process. This ensures complete scale removal without over-picking, which could damage the surface of the steel. The result is a hot-rolled, annealed, and pickled (HRAP) coil, which has a clean, matte grey finish (often called a No. 1 Finish). This HRAP coil is a commercial product in its own right, used in many industrial applications, and it is also the essential starting material for the cold rolling process.

Annealing softens stainless steelTrue

Annealing relieves internal stresses and recrystallizes the grain structure, making the material softer and more ductile.

Annealing reduces corrosion resistanceFalse

Proper annealing actually enhances corrosion resistance by dissolving harmful chromium carbides back into the steel matrix.

How does the cold rolling process enhance sheet precision and finish?

Your application demands a flawless surface and exact thickness, but the initial hot-rolled product is rough and imprecise. How do you bridge this gap? Relying on hot-rolled material for precision applications leads to poor fit, aesthetic failure, and compromised performance.

Cold rolling enhances precision by passing the annealed and pickled sheet through a series of rollers at room temperature. This process reduces thickness with very high accuracy, improves the surface finish to be smooth and bright, and increases the material's strength through work hardening.

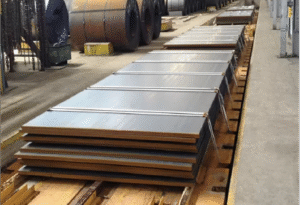

Through cold rolling, we have achieved a stainless steel sheet with remarkable dimensional accuracy, a range of controlled surface finishes, and enhanced mechanical strength. The journey from a fiery slab to this highly engineered product is nearly complete. However, before these gleaming coils and precision-cut sheets11 can be shipped to our clients—be they manufacturing companies, construction contractors, or distributors—they must pass one final, crucial gauntlet. This is the stage of final quality control and finishing. It's where we verify that every single specification has been met, from thickness and width to surface roughness and mechanical properties. This meticulous inspection and the final finishing steps, like slitting or cutting to length, are what underpin the MFY guarantee of quality. It ensures that the material arriving at a customer's facility is not just a product, but a certified, ready-to-use solution that will perform exactly as expected, every single time. This is the final promise we keep before the product is ready for distribution.

Cold rolling is where stainless steel truly earns its reputation for precision and beauty. Unlike hot rolling, which is performed above the steel's recrystallization temperature, cold rolling is done at room temperature. This fundamental difference is the key to its transformative power. Starting with a clean, annealed, and pickled coil, the cold rolling process12 employs immense force to reduce the sheet's thickness. Because the steel is not malleable from heat, the process induces significant work hardening, which increases its tensile strength and hardness. At MFY, our cold rolling mills, such as our 20-high Sendzimir mill, are marvels of precision engineering, capable of achieving thickness tolerances measured in microns. This process is about more than just making the steel thinner; it’s about imparting a superior surface finish, absolute dimensional accuracy, and tailored mechanical properties that are impossible to achieve through hot rolling alone. For our target clients, from manufacturers of precision equipment to architects designing visually stunning facades, the qualities derived from cold rolling are often the most critical.

Achieving Unparalleled Dimensional Accuracy

The primary function of cold rolling is to reduce the thickness of the steel strip with exceptionally high precision. A typical cold reduction might be from 3mm down to 0.5mm, often achieved over multiple passes. The mills used for this, like the Sendzimir mill, use a cluster of small-diameter work rolls backed by multiple larger rolls. This design minimizes roll deflection under the immense pressures, ensuring that the resulting sheet has a highly uniform thickness across its entire width and length.

Modern cold mills are equipped with advanced gauge control systems that use feedback from X-ray or laser thickness gauges to make micro-adjustments to the roll pressure and tension in real time. For instance, our systems can maintain a thickness tolerance of ±0.01mm on a 1mm thick sheet. This level of precision is critical for a client I work with in the automotive sector in India. They produce components that require automated, high-speed stamping and laser welding. Any significant thickness variation would disrupt their automated lines, causing tool wear and defective parts. The consistent gauge of our cold-rolled coils ensures their production runs smoothly and efficiently.

This dimensional control extends to the sheet's flatness and profile. Special steering and bending capabilities within the mill stands counteract any tendency for the sheet to become wavy or develop a "crown" (thicker center). The result is a perfectly flat, uniform sheet that is ideal for applications requiring a perfect fit and finish.

Crafting the Perfect Surface Finish

Cold rolling is directly responsible for the wide variety of surface finishes available on stainless steel sheets. The process starts with a matte HRAP coil (No. 1 Finish) and, through the intense pressure of highly polished work rolls, progressively smooths the surface. The standard cold-rolled finish is a dull, non-reflective finish known as 2B. It is achieved by a final, light pass through polished rolls after annealing and pickling the cold-rolled sheet. The 2B finish is the most common and versatile finish, used in everything from industrial equipment to kitchen appliances.

To achieve brighter, more reflective finishes, further processing is required. A Bright Annealed (BA)%2C%20depending%20on%20the%20stainless%20steel%20grade.)13 finish, for example, is produced by annealing the cold-rolled steel in a controlled atmosphere furnace, which prevents the formation of oxide scale and preserves the highly reflective surface imparted by the cold rolling rolls. For a mirror finish (No. 8), the sheet undergoes a series of mechanical grinding and buffing operations with progressively finer abrasives.

I recently helped a distributor in Southeast Asia select the right finish for a high-end architectural project. They needed a finish that was reflective but diffused light to avoid glare. We recommended a No. 4 "brushed" finish, which we produce by mechanically abrading a 2B sheet with a specific grit. Understanding and controlling the surface finish is a key part of how we add value. It allows us to provide a material that meets not just the functional, but also the critical aesthetic requirements of our clients.

| Finish Designation | Description | Typical Ra (μm) | Common Applications |

|---|---|---|---|

| No. 1 | Hot-rolled, annealed, and pickled. Dull, non-reflective. | 3.0 - 6.0 | Industrial applications, structural components. |

| 2B | Cold-rolled, annealed, pickled, skin passed. Smooth, dull grey. | 0.1 - 0.5 | Most common finish; appliances, chemical equipment. |

| BA (Bright Annealed) | Cold-rolled and bright annealed. Smooth, reflective. | < 0.1 | Architectural trim, food processing, kitchenware. |

| No. 4 | General purpose polished finish (brushed). | 0.3 - 0.6 | Restaurant equipment, dairy, architectural panels. |

| No. 8 | Mirror finish. Highly reflective. | < 0.05 | Ornamental trim, mirrors, architectural accents. |

Tailoring Mechanical Properties with Work Hardening

While annealing makes the steel soft and ductile, cold rolling does the opposite: it makes it harder, stronger, and less ductile. This phenomenon, known as work hardening or strain hardening, is a direct result of the plastic deformation occurring at room temperature. As the steel is squeezed between the rolls, new dislocations are generated and they entangle with each other, making further deformation more difficult. This effect can be precisely controlled by the amount of thickness reduction, known as "temper rolling" or "skin passing."

This allows us to offer stainless steel sheets in various temper conditions, such as quarter-hard, half-hard, or full-hard. A manufacturing company producing springs, cutlery, or surgical instruments might require a half-hard or full-hard material that offers high strength and holds a sharp edge. For example, the yield strength of Type 304 stainless steel can be increased from around 240 MPa in the annealed state to over 800 MPa in a full-hard condition.

This ability to precisely control the final strength provides engineers and designers with a broader palette of material properties. It’s a key strength of MFY’s integrated production model. We can take a single grade of steel and, through controlled cold rolling, engineer a range of products with different tempers, tailored to the specific performance requirements of our clients. This customization is a powerful tool, enabling our customers to optimize their designs for weight, strength, and performance.

Cold rolling increases material strengthTrue

Cold rolling induces work hardening which increases tensile strength and hardness of the steel.

Hot rolling provides better surface finishFalse

Cold rolling produces superior surface finishes compared to hot rolling which leaves a rough surface.

What are the final quality control measures before stainless steel sheets are ready for distribution?

You've received your shipment, but how can you be certain the stainless steel sheets meet every technical requirement? Assuming quality without verification is a significant risk. Defects discovered during fabrication can halt production, leading to massive financial and reputational damage for your projects.

quality control involves a battery of tests and inspections. This includes verifying dimensional accuracy14 (thickness, width, flatness) with laser sensors, conducting tensile tests15 for mechanical properties, performing surface roughness analysis, and certifying the material’s chemical composition against order specifications before final packing.

This exhaustive process, from the fiery furnace to the final meticulous inspection, illustrates the immense complexity and precision required to produce world-class stainless steel sheets. Every step is a link in a chain of quality, and at MFY, we have forged that chain to be incredibly strong. We've journeyed through the science of heating, the force of rolling, the therapy of annealing, and the precision of cold finishing. Understanding this journey is not just an academic exercise; it's the key to making informed decisions when sourcing materials that are critical to the success of your business. It highlights why a fully integrated supply chain, one that controls quality from the raw slab to the final packaged sheet, is your greatest asset in a competitive global market. This comprehensive approach ensures that the material you receive is not just a commodity but a reliable, high-performance solution engineered for your success.

The final quality control stage is the gatekeeper that stands between our production line and our customer. At MFY, this is not a random spot-check; it is a systematic and rigorous validation process that ensures every sheet and coil leaving our facility adheres strictly to the customer's specifications and international standards. This final assurance is critical for our clients, whether they are distributors who stake their reputation on the products they sell, or engineering contractors whose projects' safety and longevity depend on material integrity. Our quality control department operates as an independent arbiter, armed with advanced testing equipment and a zero-defect mindset. They are the final checkpoint in our promise of agility, resilience, and continuous evolution, providing the certified proof that our integrated supply chain has delivered a product of uncompromising quality.

Comprehensive Dimensional and Surface Verification

Before a coil is packaged or cut into sheets, it undergoes a final, comprehensive inspection. Continuous, non-contact laser gauges perform a final scan of the entire coil's length, verifying that the thickness and width are within the specified tolerances one last time. In parallel, advanced surface inspection systems, using high-speed cameras and AI-powered image analysis, scan for any potential defects such as scratches, pits, roll marks, or variations in finish. For a client in the high-purity tubing industry, even a microscopic surface scratch can be a point of contamination, so our automated 100% surface inspection is not a luxury, it's a necessity.

Simultaneously, the sheet's flatness is measured. A sample section is often laid on a granite inspection table, and its deviation from perfect flatness is quantified. For applications like architectural cladding or precision machine beds, flatness is a critical parameter. For example, we guarantee a flatness tolerance that is often 50% tighter than the standard ASTM A480 specification for clients who require it.

This meticulous, data-driven verification of the product's physical attributes ensures that what the customer ordered is exactly what they receive. Every coil or package of sheets is accompanied by a detailed inspection report that provides a transparent record of its dimensional properties. This documentation is a cornerstone of the trust we build with our clients.

Mechanical and Chemical Properties Validation

Beyond just looking right, the steel must perform right. To certify its mechanical properties, samples are taken from the coil and subjected to a battery of tests in our materials laboratory. The most common is the tensile test, where a sample is pulled until it breaks. This test provides critical data on yield strength, ultimate tensile strength, and elongation—key indicators of the material's strength and ductility. For a construction contractor building in a seismic zone, the certified yield strength and elongation values are not just numbers; they are essential inputs for their structural engineering calculations.

Hardness tests (e.g., Rockwell or Vickers) are also performed to confirm the material is in the correct temper. Additionally, for specific applications, we may conduct bend tests to ensure formability or impact tests (Charpy) to measure toughness, especially for materials intended for low-temperature service.

The material's chemical composition is also re-verified using optical emission spectrometry. A sample is vaporized, and the light it emits is analyzed to give a precise breakdown of its elemental content, from nickel and chromium to trace elements. This final chemical check guarantees that the correct grade was produced and that it meets the required corrosion resistance and performance standards. All these results are compiled into a Material Test Certificate (MTC) or Mill Test Report (MTR) that is shipped with the product.

Finishing, Packing, and Traceability

Once a coil has passed all quality inspections, it proceeds to final finishing. This may involve slitting the master coil into narrower widths or using a cut-to-length line to produce flat sheets of a specific size. Precision and care are paramount here to ensure burr-free edges and accurate dimensions. At MFY, our slitting and cut-to-length lines are equipped with their own quality checks to ensure this final processing step maintains the integrity of the product.

Packing is the final, crucial step to protect the product during transit and storage. Depending on the finish and destination, coils and sheets are interleaved with paper, wrapped in waterproof plastic and burlap, and secured to robust wooden pallets or "skids." For highly polished or delicate surfaces, a protective PVC or PE film is applied to the surface of the sheet, which the end-user can peel off after fabrication. I have seen the consequences of poor packaging from other suppliers—water stains, scratches, and edge damage that render a perfect product useless by the time it arrives. Our meticulous packing standards are designed to ensure our products arrive at our clients' facilities in the same pristine condition they were in when they left our inspection bay.

ly, every coil and package is labeled with a unique identification number that links it directly to its production data and the MTC. This robust traceability is a core part of our quality system. If a client has any questions about a specific piece of material, we can retrieve its entire life history, from the original slab to the final test results, in minutes. This is the final expression of our commitment to quality and accountability.

Laser gauges verify sheet dimensionsTrue

Non-contact laser gauges perform final scans to ensure thickness and width tolerances are met.

Chemical composition isn't verifiedFalse

Optical emission spectrometry is used to re-verify the material's chemical composition before shipping.

Conclusion

This detailed journey, from a raw hot slab to a precision-engineered, quality-verified stainless steel sheet, is the backbone of modern industry. At MFY, our fully integrated supply chain ensures that at every critical stage, quality, precision, and performance are meticulously controlled and certified for our clients.

-

Discover key temperatures crucial for achieving malleability in steel processing. ↩

-

Learn how high-pressure descaling enhances surface quality in stainless steel. ↩

-

Understand the impact of heating precision on steel's final quality and performance. ↩

-

Discover how thermal uniformity prevents defects during the steel rolling process. ↩

-

Find out the pressure levels that ensure optimal descaling and surface quality. ↩

-

Understand how hot rolling refines grain structure and enhances mechanical properties ↩

-

Learn about annealing's importance in relieving stress and improving workability ↩

-

Gain insights into AGC systems' role in precision and quality control ↩

-

Learn how heating affects stainless steel's internal structure and enhances ductility and corrosion resistance ↩

-

Discover how pickling and cold rolling ensure precise surface finish and strengthen stainless steel sheets ↩

-

Discover how cold-rolled coils ensure quality and customer satisfaction ↩

-

Learn the enhanced properties of steel achieved through cold rolling ↩

-

Understand the steps to achieve a Bright Annealed finish for aesthetic appeal ↩

-

Understand the technology used for ensuring precise dimensions in steel products ↩

-

Learn how tensile tests assess the strength and ductility of steel ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.