304 vs 201 Stainless Steel Plate: Composition, Performance & Cost

Choosing the wrong stainless steel can be a costly mistake. It can lead to project failure or unnecessary overspending. Understanding the core differences makes the decision clear and simple.

The best choice between 304 and 201 stainless steel depends on balancing performance with budget. 304 grade offers superior corrosion resistance for demanding environments, while 201 is a more cost-effective alternative for less critical, indoor applications. Your project's specific needs ultimately dictate the right material.

In my role at MFY, I speak with clients every day about this exact question. It's one of the most common decisions our partners in manufacturing and construction have to make. The choice isn't just about technical specifications; it's a strategic business decision that impacts budgets, product longevity, and brand reputation. Let's break down the factors together so you can make the most informed choice for your supply chain.

What Are the Key Compositional Differences Between 304 and 201 Stainless Steel?

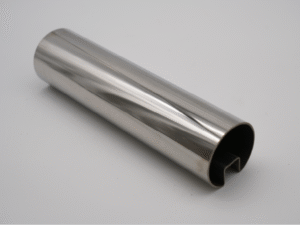

On the surface, these two grades look identical. But their internal chemistry tells a completely different story, impacting everything from rust resistance to cost. Let's look inside.

The primary compositional difference is the nickel and manganese content. Grade 304 contains at least 8% nickel, which provides excellent corrosion resistance. Grade 201 substitutes much of this expensive nickel with more affordable manganese and nitrogen, resulting in lower cost but reduced protective properties.

At MFY, we see the results of these chemical differences every day. It's the classic trade-off between performance and cost, and it all starts here. The decision to use one over the other is a strategic one, and understanding the "why" behind the chemistry is the first step for any procurement manager or engineer.

The Role of Nickel (Ni) in 304

Nickel is the hero element in 304 stainless steel. It stabilizes the austenitic structure of the steel, which is what gives it fantastic formability and toughness, even at low temperatures. More importantly, nickel is the key ingredient for its superior corrosion resistance, especially against acids and chlorides. However, nickel is a volatile commodity, and its high price is the main driver of 304's cost. This is why our clients in the chemical processing or marine industries never compromise; for them, the performance enabled by nickel is non-negotiable.

The Manganese (Mn) Substitution in 201

Grade 201 was developed during a time of nickel shortages as a cost-saving alternative. By increasing the manganese and nitrogen content, manufacturers could reduce the amount of nickel needed while still maintaining an austenitic structure. While manganese is excellent for hardness and strength, it simply does not provide the same level of corrosion protection as nickel. This compositional trade-off makes 201 a smart, economical choice for industries like consumer goods or indoor architectural trim, where the material won't face harsh elements.

| Element | Grade 304 (Typical %) | Grade 201 (Typical %) | Impact |

|---|---|---|---|

| Chromium (Cr) | 18 - 20 | 16 - 18 | Primary element for corrosion resistance in both grades. |

| Nickel (Ni) | 8 - 10.5 | 3.5 - 5.5 | Key for superior corrosion resistance and formability. |

| Manganese (Mn) | < 2 | 5.5 - 7.5 | Replaces nickel to lower cost; increases hardness. |

How Do 304 and 201 Stainless Steel Plates Perform Under Different Conditions?

A steel plate fails unexpectedly on a project. This causes costly downtime, repairs, and damages your reputation. Understanding the performance limits of each grade prevents these failures.

304 stainless steel performs exceptionally well in corrosive or wet environments due to its high nickel content. 201 steel performs well in dry, indoor conditions but is susceptible to rust when exposed to moisture, salts, or industrial pollutants. 304 also offers superior formability for complex designs.

Performance is where the chemical differences we just discussed become real-world results. For our clients, this is the most critical factor. Selecting a material that can't withstand its operational environment is a recipe for disaster. We always advise our partners to think about the worst-case scenario the material will face, not just the day-to-day conditions. This foresight is what separates a reliable product from a liability.

Corrosion Resistance: The Deciding Factor

This is the single biggest performance difference. The high chromium and nickel content in 304 creates a stable, passive layer on the steel's surface that protects it from rust and corrosion. It can handle everything from food acids to saltwater spray. In contrast, 201's lower chromium and nickel content make its passive layer weaker and more prone to breaking down, especially in the presence of chlorides. I once had a client in Southeast Asia who tried to save costs by using 201 for outdoor railings near the coast. Within a year, they were dealing with significant rust staining, forcing a costly replacement. This experience taught them a valuable lesson about matching the material to the environment.

Mechanical Properties: Formability and Strength

While both are austenitic steels, 304 generally has better ductility and formability. This means it can be bent, stamped, and drawn into complex shapes without cracking. This is vital for products like deep-drawn kitchen sinks or intricate automotive parts. Grade 201, due to its higher nitrogen content, has slightly higher yield strength but is less ductile. It can be more prone to work-hardening, which can make fabrication more challenging. At MFY's processing facilities, we adjust our machinery settings to account for these differences to ensure a perfect finish for our clients, whether they choose 304 or 201.

| Performance Metric | Grade 304 | Grade 201 |

|---|---|---|

| Corrosion Resistance | Excellent | Poor to Fair |

| Formability / Ductility | Excellent | Good |

| Weldability | Excellent | Good |

| Toughness | Excellent | Good |

What Are the Cost Implications of Choosing 304 Over 201 Stainless Steel?

Your project is running over budget. Material costs are a major factor, and you need to find savings. Understanding the price difference between these grades is key to effective planning.

201 stainless steel is significantly less expensive than 304, mainly because manganese costs far less than nickel. This makes 201 a compelling choice for large-scale projects. However, this initial saving can be erased by future replacement costs if the material is used in an inappropriate environment.

In my global business director role, I analyze market trends constantly. The price of nickel on the London Metal Exchange directly influences the cost of 304 stainless steel. This volatility can make budgeting difficult. This is where the strategic value of 201 becomes clear. It offers price stability. The decision is not just about which material is cheaper today, but which one offers the best value over the entire lifecycle of the product. This shift in thinking from upfront cost to total cost of ownership is crucial for building a resilient supply chain.

Upfront Savings vs. Total Cost of Ownership (TCO)

The immediate appeal of 201 is its lower price per kilogram. For a large order of stainless steel plates, this can translate into tens of thousands of dollars in upfront savings. This is very attractive for budget-conscious sectors. However, we encourage our partners to calculate the TCO. If a 201 plate used in a damp environment fails in three years and a 304 plate would have lasted for twenty, the initial savings are gone. The cost of labor for removal and installation, plus the operational downtime, makes the "cheaper" option far more expensive in the long run. An informed material strategy always considers the full picture.

The Nickel Market's Influence

The price of 304 is directly tied to global nickel prices. Geopolitical events, mining outputs, and demand from the electric vehicle battery market can cause prices to swing dramatically. This makes 201, with its reliance on the more stable manganese market, a predictable and budget-friendly option. For manufacturers who need to lock in material costs for long-term projects, 201 provides a level of financial security that 304 cannot always offer. At MFY, we help our clients navigate this volatility with strategic sourcing and hedging options, but the fundamental price difference between the grades remains a key planning factor.

Which Applications Are Best Suited for 304 Versus 201 Stainless Steel Plates?

You're using a high-performance material for a simple job. This is over-engineering and wastes money. Matching the steel grade to the application's true needs is critical for efficiency.

Grade 304 is the industry standard for food and beverage equipment, medical instruments, chemical tanks, and outdoor architectural features. Grade 201 is an excellent choice for indoor decorative applications, kitchen utensils, automotive trim, and structural components in dry environments where high corrosion resistance is not required.

This is where theory meets practice. Aligning the material choice with the specific operational requirement is the essence of smart engineering and procurement. At MFY, our goal is to ensure our clients aren't just buying steel plates; they are buying the right solution for their specific problem. Over-specifying with 304 when 201 would suffice is just as inefficient as under-specifying and risking failure. A successful business optimizes every part of its supply chain, and that begins with choosing the right raw materials.

When to Insist on 304

You should always choose 304 stainless steel when the application involves:

- Food Contact: Its high corrosion resistance ensures it won't leach metals into food or harbor bacteria. Think commercial kitchens, dairy processing, and breweries.

- Corrosive Environments: This includes marine applications, chemical processing plants, and outdoor architecture in coastal or industrial areas with high pollution.

- Sanitary Requirements: Medical equipment, pharmaceutical manufacturing, and cleanrooms demand the cleanability and non-reactive surface of 304.

- Extreme Temperatures: 304 maintains its strength and structure well at both high and cryogenic temperatures.

Where 201 Makes Smart Business Sense

Grade 201 is the optimal, cost-effective choice for:

- Indoor Decorative Trim: Wall panels, elevator doors, and retail displays where aesthetics are key but exposure to moisture is minimal.

- Consumer Goods: Kitchen appliances (like blender bases), utensils, and cookware that are regularly washed and dried.

- Automotive: Interior trim and some exterior parts in regions where road salt is not used.

- Structural Components: Brackets, frames, and supports used in controlled, indoor environments.

| Grade | Common Applications | Key Justification |

|---|---|---|

| 304 | Kitchen Sinks, Chemical Tanks, Outdoor Railings | Superior Corrosion Resistance & Hygiene |

| 201 | Indoor Wall Panels, Utensils, Automotive Trim | Cost-Effectiveness & Good Aesthetics |

What Recommendations Can Be Made When Selecting Between 304 and 201 Stainless Steel?

You're at a crossroads, still unsure which to choose. The wrong decision is costly and hard to fix. Let us provide a clear framework to help you decide confidently.

First, rigorously assess the end-use environment. If the plate will face moisture, chemicals, or salt, you must choose 304. For dry, indoor applications driven by budget, 201 is a smart choice. When in doubt, always consult a trusted material expert like our team at MFY.

Making the final call is about asking the right questions. As a leader in the stainless steel supply chain, we see our role as more than just a supplier. We are a partner in our clients' success. We believe an informed customer is the best customer, because they make strategic decisions that lead to long-term growth. This final choice is where you can truly create a competitive advantage through an intelligent material strategy.

A Practical Decision-Making Framework

Before you place your next order, walk through this simple checklist with your team:

- Environment Analysis: Will the part be indoors or outdoors? Will it be exposed to water, salt, cleaning agents, or industrial chemicals? Be honest and thorough here.

- Budget Constraints: What is the target cost for this component? Is the primary driver the upfront price or the long-term lifecycle value?

- Fabrication Needs: Does the part require deep drawing, complex bending, or extensive welding? If so, the superior formability of 304 might reduce manufacturing waste and time.

- Customer Expectations: What is the expected lifespan of the final product? What level of quality and durability does your brand promise to your customers?

Partnering for Success

Ultimately, you don't have to make this decision alone. The nuances between grades can be complex, and market conditions are always changing. That's why building a relationship with a knowledgeable supplier is so important. At MFY, our technical sales team has decades of combined experience across dozens of industries. We can analyze your application, understand your business goals, and recommend the material that provides the perfect balance of performance, cost, and long-term value. This collaborative approach ensures you get the right material, at the right price, every single time.

Conclusion

Choosing between 304 and 201 steel is a strategic balance of performance against cost. Aligning your material to the application's real-world demands ensures durability and economic efficiency.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.