knowledge

Restoring Mill Finish: Professional Techniques to Renew Stainless Steel Surfaces

Restoring a stainless steel mill finish involves a systematic process of cleaning, surface preparation, and using mechanical or chemical techniques to renew its protective passive layer. This enhances the material’s lifespan and maintains its aesthetic quality. A proper understanding of the finish’s importance helps prevent corrosion, saving on costs and reinforcing quality standards. Techniques range from using non-woven abrasive pads to chemical passivation, each chosen based on the damage type. Regular maintenance with mild soap and water, avoiding harsh chemicals, ensures the surface remains in optimal condition….

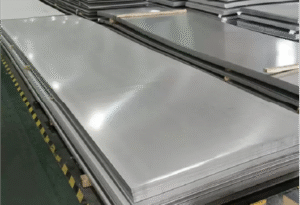

The Top 7 Common Defects in Stainless Steel Sheets and How to Spot Them

Imperfect stainless steel sheets can lead to project delays and cost overruns due to hidden defects like surface scratches, dents, corrosion spots, uneven color, delamination, wavy deformation, and edge damage. Identifying these flaws through diligent inspection is crucial for maintaining material integrity and avoiding costly failures. As a leader in the stainless steel industry, MFY emphasizes meticulous quality control and prevention strategies, including comprehensive visual inspections, precision measurement tools, and non-destructive testing methods. Understanding the root causes of these defects from production to handling is key to ensuring high-quality results and protecting your reputation in competitive markets….

Manufacturer’s Guide to Addressing 5 Critical Stainless Steel Sheet Imperfections

This guide delves into the five critical imperfections that affect stainless steel sheets: surface defects, non-uniform thickness, edge waviness, pitting, and inconsistent corrosion resistance. It explores the causes of these flaws during manufacturing and their impact on product performance and aesthetics. The article provides solutions for manufacturers to minimize these issues through advanced process controls, inspection technology, and optimized material handling. It also discusses best practices for quality control, emphasizing data-driven and predictive systems to ensure high-quality stainless steel sheets….

Pitting vs. Crevice: Identifying and Mitigating Stainless Steel Corrosion Risks

Pitting and crevice corrosion pose significant risks to stainless steel assets, potentially leading to catastrophic failures. Understanding their distinct causes is crucial for effective mitigation. Pitting occurs due to chemical breakdown on open surfaces, while crevice corrosion emerges in shielded gaps from stagnant conditions. Mitigation involves choosing materials with higher resistance, like 316L or duplex grades, and employing smart design practices to eliminate tight gaps. By differentiating these corrosion types and applying the right strategies, you can ensure the long-term reliability of your stainless steel applications….

The Definitive Guide to Cleaning Stainless Steel Sheets for Pre-Installation

Proper cleaning of stainless steel sheets before installation is crucial to prevent corrosion and maintain aesthetic quality. This guide outlines a five-step process: gathering the right materials, inspecting for stains, applying suitable cleaning solutions, gentle scrubbing, and thorough rinsing and drying. Using microfibre cloths and mild detergents, while avoiding abrasives, ensures effective cleaning without damaging the passive layer. MFY emphasizes this process as a critical investment in the project’s longevity and performance, reducing future maintenance costs….

Corrosion Risk Assessment: Water Exposure and Stainless Steel Grades

The article explores the importance of choosing the right stainless steel grade for water applications to prevent corrosion-related failures. It details how corrosion risk assessment involves analyzing water chemistry, temperature, and flow rate to select appropriate stainless steel grades, such as 304 for freshwater and 316L for saltwater. Common corrosion types like pitting and crevice corrosion are explained, emphasizing the need for correct grade selection and proactive maintenance to ensure long-term durability and cost-effectiveness. The piece also highlights the environmental factors influencing corrosion rates and recommends best practices for preventing corrosion in stainless steel water systems….

Understanding Fitting Corrosion in Stainless Steel Water Applications

Stainless steel water systems can suffer from unexpected corrosion, leading to costly repairs and downtime. This article explores the mechanisms of corrosion in stainless steel, particularly in water applications, and identifies key factors such as high chloride concentrations, low pH, stagnant water, and high temperatures as primary culprits. Understanding the types of corrosion like pitting, crevice, and stress corrosion cracking is crucial for prevention. Environmental factors and material selection play pivotal roles, with solutions including the use of higher-grade alloys, protective treatments, and improved system design. A proactive, lifecycle approach involving thorough analysis, proper material choice, and regular maintenance is essential for preventing corrosion and ensuring system longevity….

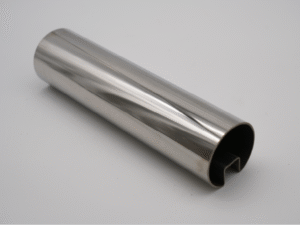

Industrial-Scale Rust Remediation for Stainless Steel Coils and Pipes

Rust on stainless steel can compromise structural integrity and project timelines. Understanding its causes, such as contamination and environmental exposure, is crucial for prevention. Effective rust remediation combines proactive measures, like selecting the right steel grade and controlling environmental factors, with advanced techniques like laser cleaning and automated surface restoration. These methods preserve the material’s integrity and are more eco-friendly. Maintaining a rust-free surface involves regular cleaning, inspection, and immediate treatment of any signs of corrosion. Implementing a comprehensive maintenance program ensures the longevity and performance of stainless steel products….

Advanced Methods for Derusting Stainless Steel Pipes

Rust on stainless steel pipes can compromise their structural integrity and project value. Advanced derusting methods, including chemical, mechanical, and non-destructive laser cleaning techniques, can effectively remove rust and prevent future corrosion. Assessing the rust’s severity accurately guides the choice of derusting method, ensuring cost-efficient and effective outcomes. Chemical treatments, when applied correctly, dissolve rust while preserving the stainless steel. For severe rust, mechanical cleaning is necessary, while advanced methods like laser cleaning offer non-destructive solutions. Prevention through passivation and environmental control ensures the long-term preservation of stainless steel assets….

Water Damage Prevention: Selecting Corrosion-Resistant Stainless Steel Grades

Water exposure can lead to significant damage in steel structures due to corrosion. Selecting the right stainless steel grade is crucial to preventing rust and ensuring structural integrity. By understanding the environment, such as freshwater or saltwater exposure, and selecting appropriate grades like 316L or Duplex, you can effectively manage corrosion risks. MFY specializes in guiding clients through these choices, ensuring a strategic investment in materials that provide longevity and reliability, reducing long-term costs and avoiding failures….