How to Ensure Quality in Stainless Steel Plate Fabrication

Fabrication defects risk project failure and costly rework. This uncertainty can derail timelines. A meticulous, step-by-step quality assurance process[^1] is the only way to guarantee performance and reliability.

Ensuring quality in stainless steel plate fabrication requires a comprehensive approach. This includes correct material selection, precision cutting and forming, proper welding techniques, and rigorous final inspection. Each stage must adhere to strict quality control standards to guarantee structural integrity and performance.

As the Global Business Director at MFY, I've seen firsthand how a lapse in quality at any stage can compromise an entire project. It's not just about the final product; it's about the trust our clients place in us. Let's break down the critical stages of fabrication and explore how to embed quality at every step, transforming a standard process into a framework for operational excellence.

What are the key initial steps in stainless steel plate fabrication?

Unclear project requirements lead to costly errors. Misinterpretations cause material waste and delays. The solution is detailed planning, material verification, and surface preparation before any work begins.

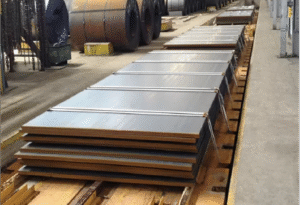

The key initial steps are meticulous planning, thorough material inspection, and proper surface preparation. This involves reviewing engineering drawings, verifying the steel grade and dimensions, and cleaning the plate to remove contaminants that could affect subsequent processes like welding.

The initial phase is where quality is born. Before a single cut is made, we must build a digital blueprint for success. At MFY, we see this as more than just reviewing drawings; it's about creating a 'digital twin[^2]' of the final product. This allows us to run simulations and predict potential issues before they materialize on the workshop floor, a strategy that saves immense time and resources. I remember a complex project for a machinery manufacturer in Germany where our initial digital analysis identified a potential stress point in the design. By addressing it before fabrication, we prevented a costly post-production modification. This proactive approach is central to a modern quality assurance framework.

Material Verification and Traceability

Once the plan is set, the physical material must be flawless. Every plate that enters our facility is checked against its Mill Test Certificate (MTC)[^3]. We verify its chemical composition, mechanical properties, and dimensions. This isn't just a box-ticking exercise; it's about guaranteeing that the material entering the supply chain is exactly what the client’s application demands.

Surface Preparation

Finally, the plate must be prepared. Any surface contaminants like oil, grease, or scale can compromise the integrity of a weld or the effectiveness of a surface finish. We employ rigorous cleaning protocols to ensure the stainless steel is pristine. This simple but critical step prevents a host of downstream problems and is a non-negotiable part of our quality process.

How to select the right stainless steel grade for specific applications?

Choosing the wrong steel grade causes premature failure. Corrosion or mechanical stress can ruin a project. The solution is matching the grade's properties to the application's specific environment.

Selecting the right grade involves analyzing the application's specific needs. Consider factors like corrosion resistance, mechanical strength, temperature exposure, and weldability. Common grades like 304, 316, and 430 each offer unique properties suited for different environments.

Selecting the correct grade is perhaps the most critical decision in the entire process. It’s a balance of performance, cost, and longevity. As a company with a fully integrated supply chain, we have a unique perspective on this. We don't just sell steel; we provide solutions. A client in the construction sector once approached us for a coastal project, initially specifying Grade 304 for cost reasons. After analyzing the high-saline environment, I personally recommended they upgrade to 316L. The slightly higher initial investment would prevent catastrophic corrosion-related failures down the line, saving them millions in the long run. This is what partnership looks like. It's about leveraging our deep industry knowledge to protect our clients' interests and ensure the final fabricated product is fit for purpose, not just for the budget.

Common Stainless Steel Grades Compared

Understanding the fundamental differences is key. Here is a simple breakdown:

| Grade | Key Characteristics | Common Applications |

|---|---|---|

| 304 | Good corrosion resistance, excellent formability | Kitchen equipment, architectural paneling, storage tanks |

| 316/316L | Superior corrosion resistance, especially against chlorides | Marine hardware, chemical processing, medical implants |

| 430 | Good corrosion resistance, magnetic | Automotive trim, decorative applications, refrigerator panels |

This decision directly impacts the structural integrity and lifespan of the final product. Getting it right is fundamental to quality.

What techniques are essential for precise cutting and shaping?

Inaccurate cuts lead to poor fit-up. This compromises structural integrity and aesthetics. The solution is using advanced cutting technologies for clean, precise results every single time.

Essential techniques for precise cutting include laser cutting, plasma cutting, and waterjet cutting. For shaping, press braking and rolling are key. The choice of technique depends on the plate thickness, required precision, and desired edge finish.

This is where advanced technology truly shines. In today's market, speed and customization are everything. To meet these demands without sacrificing quality, we rely on precision engineering powered by automation. At MFY, our workshops are equipped with state-of-the-art CNC (Computer Numerical Control) machines that translate digital designs into physical cuts with micron-level accuracy. This isn't just about making a clean edge; it's about minimizing the Heat-Affected Zone (HAZ)[^4], which can alter the properties of the steel near the cut. By investing in advanced laser and waterjet cutters, we reduce material waste, eliminate the need for secondary finishing processes, and ensure that every component fits together perfectly during assembly. This investment in technology is a direct investment in the quality and cost-efficiency we deliver to our clients.

Cutting Technologies at a Glance

- Laser Cutting: Offers exceptional precision and a clean edge finish, ideal for intricate designs and thinner plates.

- Plasma Cutting: A faster and more cost-effective option for thicker plates, balancing speed with good accuracy.

- Waterjet Cutting: Uses a high-pressure stream of water and abrasive to cut without generating heat, preserving the material's properties entirely.

Forming and Bending with Precision

Shaping the cut plate requires the same level of precision. Modern press brakes with CNC controls allow us to create complex bends with repeatable accuracy, ensuring every fabricated part matches the design specifications perfectly.

How to ensure proper welding and joining practices?

Improper welding creates weak points. These joints are prone to corrosion and structural failure. The solution is using the right technique, filler material, and meticulous post-weld cleaning.

Ensuring proper welding involves selecting the correct method (TIG, MIG), using a compatible filler metal, and maintaining a clean environment. Proper heat control is crucial to prevent distortion. Post-weld cleaning and passivation are essential to restore corrosion resistance.

A weld is often the most critical point in a fabrication. It can also be the weakest if not performed correctly. This is where technology meets human skill. While we use advanced welding machines, the quality of the weld comes down to the expertise of the operator. That's why we invest heavily in training and certification for our workforce. A certified welder understands the metallurgy of stainless steel. They know how to control heat input to prevent warping and sensitization, a phenomenon that can destroy the steel's corrosion resistance. I once visited a food processing plant where a competitor's improperly welded tank had developed crevice corrosion, creating a hygiene risk. It served as a powerful reminder that proper welding, followed by essential post-weld treatments, is not just a technical requirement but a matter of safety and reliability.

Welding Method Selection

- TIG (Tungsten Inert Gas): Provides high-quality, precise welds. It's slower but ideal for applications requiring a superior aesthetic finish and strong joints.

- MIG (Metal Inert Gas): A faster process suitable for long, continuous welds. It offers a good balance of speed and quality for many structural applications.

Post-Weld Treatment is Non-Negotiable

After welding, the job isn't done. The area must be thoroughly cleaned to remove heat tint (oxidation). Then, a process called passivation is often required, which involves treating the surface with a mild acid to restore the protective chromium oxide layer that gives stainless steel its "stainless" quality. Skipping this step is a common but critical mistake.

What are the final inspection and testing steps to guarantee quality?

Hidden defects can cause catastrophic failure later. Undetected flaws undermine the entire project's integrity. The solution is a multi-step inspection using both visual and non-destructive methods.

Final inspection includes visual checks for surface defects and dimensional accuracy verification against drawings. Non-Destructive Testing (NDT) methods like dye penetrant testing or ultrasonic testing are used to detect hidden flaws in welds and the material itself.

The final inspection is our last line of defense and our ultimate promise of quality to the client. It's where we validate every preceding step. This process must be systematic and unforgiving. Our quality assurance framework doesn't just rely on the human eye. We employ a range of Non-Destructive Testing (NDT) techniques to look beneath the surface. This is how we meet and exceed stringent international standards. For a high-pressure vessel project for the energy sector, we used ultrasonic testing on every single weld seam to ensure there were no internal voids or cracks. This data, along with all material certificates and process reports, was compiled into a comprehensive quality dossier for the client. This level of transparency and documentation provides complete traceability and, more importantly, peace of mind. It demonstrates that our commitment to quality is backed by verifiable proof.

Key NDT Methods

| Method | Purpose |

|---|---|

| Visual Testing (VT) | Checks for surface imperfections, dimensions, and finish. |

| Dye Penetrant (PT) | Reveals surface-breaking cracks or pores. |

| Ultrasonic (UT) | Detects internal flaws like cracks and voids. |

| Radiographic (RT) | Provides an X-ray view to identify internal defects. |

This final, rigorous check ensures that the product leaving our facility is not only built to specification but engineered for safety, durability, and performance.

Conclusion

Ultimately, quality in stainless steel fabrication isn't a single action but a commitment. It's about integrating meticulous planning, advanced technology, and skilled execution at every stage. This ensures the final product is not just built, but engineered for lasting performance and reliability.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.