Stainless Steel Sheet Packaging Standards: Coil vs Flat Pack, PE Film vs Paper

Are you worried that your next shipment of stainless steel sheets will arrive scratched, corroded, or damaged? Improper packaging can quickly turn a valuable asset into a costly liability. This can lead to project delays, budget overruns, and damage to your professional reputation, all from a preventable issue.

The standard for packaging stainless steel sheets involves choosing between coils or flat packs and selecting protective layers like PE film or paper interleaving. This decision is vital for preventing surface damage, corrosion, and logistical challenges, guaranteeing the material's quality from our facility to your final application.

The choice of packaging is far more than a simple protective measure; it's a strategic decision that directly influences your storage capacity, handling efficiency, and even your production speed. Throughout my career as the Global Business Director at MFY, I’ve consistently seen how a well-considered packaging strategy empowers our clients, streamlining their operations and preventing costly setbacks.

This decision is not merely about choosing a box. It's about creating a tailored solution that balances protection, cost, and end-use functionality. For instance, a client in a high-humidity market like Southeast Asia might find that standard paper interleaving, while cost-effective, is insufficient to prevent moisture-related surface issues during a long sea voyage. This highlights a critical truth: the "best" packaging is a holistic solution, not a one-size-fits-all product. It requires a deeper look into your specific circumstances, weighing factors like climate, shipping duration, and handling capabilities against industry benchmarks like ASTM standards1. Let's delve into the specifics to equip you to make the optimal choice.

What Are the Standard Packaging Options for Stainless Steel Sheets?

Struggling to decide between coils and flat-packed sheets for your upcoming project? Selecting the wrong format can introduce unforeseen handling challenges and create significant bottlenecks in your production line. At MFY, we prioritize aligning the packaging format with your unique workflow to save you valuable time and money.

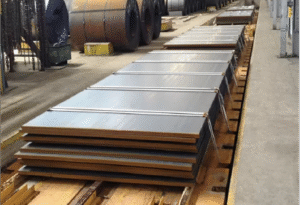

Standard packaging for stainless steel sheets primarily consists of two formats: coils, which are continuous rolls ideal for automated processing lines, and flat packs, which are pre-cut, stacked sheets perfect for jobs requiring specific dimensions. Both are secured on pallets or skids for transport with protective layering.

The decision between a multi-ton coil and a neatly organized stack of sheets extends far beyond initial convenience. This choice has a ripple effect throughout your entire supply chain, influencing everything from the moment the material is unloaded at your facility to its final transformation in your manufacturing process. I recall a key client of ours, a major manufacturer of commercial kitchen equipment in India, who initially insisted on ordering only flat-packed sheets. This format was perfect for their smaller, custom fabrication jobs. However, as their business grew, they found that for their high-volume production lines, the switch to stainless steel coils brought about a revolutionary change. By feeding the coils directly into their automated stamping and cutting machines, they drastically reduced material waste from offcuts and minimized downtime between loading new stock. Their journey underscores a vital point: the "standard" or "best" choice is fundamentally tied to your operational scale, in-house machinery, and project requirements. As we explore this further, we will dissect the unique benefits and considerations of each format, providing you with the clarity needed to determine whether coils or flat packs will deliver superior efficiency and value for your business.

The selection of a packaging format is a foundational decision in the procurement of stainless steel. It’s not just about receiving steel; it’s about receiving it in a state that seamlessly integrates with your operations and accelerates your path to success. The implications cover everything from logistics and labor to material yield and production velocity. An informed choice here can be a significant competitive advantage, while a misaligned one can lead to hidden costs and operational friction. This deep dive will provide a comprehensive framework for making that critical decision, breaking down the anatomy of each option and connecting it to real-world applications and challenges. We will move beyond simple definitions to offer a strategic analysis that empowers you to optimize your supply chain from the very first step.

The Anatomy of Stainless Steel Coil Packaging

The packaging for a stainless steel coil is a multi-layered defense system designed to protect a massive, continuous sheet of high-value material during transit and storage. The coil is typically wound around a central core, or "eye." The orientation of this eye—either vertical ("eye to the sky") or horizontal ("eye to the side")—is a critical first consideration, determined by the handling equipment available at both the supplier's and the client's facilities. Once wound, the coil is secured with robust steel or high-tensile plastic strapping to prevent it from unwinding. The entire coil is then enveloped in protective wrappings. This usually starts with a layer of Volatile Corrosion Inhibitor (VCI) paper or film, which releases a vapor that forms a protective molecular layer on the steel's surface, actively preventing rust. This is often followed by a waterproof plastic film and a final layer of durable kraft paper or even a hardboard shell for maximum protection against physical impacts and moisture. ly, sturdy edge protectors are applied to the coil's circumference to prevent dents and damage during handling.

This robust packaging is essential because coils are the lifeblood of high-volume, automated manufacturing. Consider an automotive components manufacturer, a typical client for MFY. For them, efficiency is paramount. By receiving stainless steel in coil form, they can feed it directly into their progressive die stamping or roll forming lines. This continuous process minimizes the changeover time that would be required if they were loading individual sheets, leading to a significant increase in production line efficiency. One of our partners in the automotive sector reported a 15% increase in production line efficiency after transitioning from flat sheets to coils, simply by eliminating the intermittent loading process and reducing scrap material generated between sheets.

The data supports this preference for large-scale operations. A standard stainless steel coil can weigh anywhere from 3 to 10 metric tons, containing hundreds or even thousands of linear meters of material. This scale presents logistical considerations; handling such weights requires specialized overhead cranes or C-hooks, and storage demands significant, well-planned space. However, the trade-off is superior material utilization. Because the material is continuous, manufacturers can nest parts more effectively and program their cutting lines to minimize scrap, a stark contrast to the waste often generated from the leftover sections of fixed-size flat sheets. This efficiency in material yield is a powerful financial incentive that often outweighs the initial investment in heavy-duty handling equipment.

Deconstructing the Flat Pack Standard

Flat pack packaging, also known as cut-to-length sheet packaging, offers a more accessible and manageable alternative to coils. The process begins with the stainless steel sheets being cut to precise, pre-determined dimensions. These sheets are then carefully stacked on top of one another on a sturdy wooden pallet or skid, which forms the foundation of the package. A crucial element in this process is the interleaving material placed between each individual sheet. This can be acid-neutral paper or a thin layer of plastic film, serving the critical function of preventing metal-on-metal contact, which can cause scratches and abrasions during transit. The entire stack is then securely fastened to the pallet with steel or polyester strapping. To protect against environmental factors, the stack is typically shrouded in waterproof materials, such as heavy-duty plastic sheeting or VCI-treated paper, before being enclosed in a custom-built wooden crate or a hardboard casing for final protection.

The primary advantage of the flat pack format lies in its convenience and suitability for a wide range of applications, particularly those that do not involve high-volume automated production. It is the preferred choice for smaller fabrication shops, architectural projects, and maintenance and repair operations. I recently worked with a construction contractor in the Middle East who was fabricating intricate façade panels for a new commercial tower. They required precisely cut 316L stainless steel sheets delivered directly to the construction site. For them, flat packs were the only logical solution. The pre-cut dimensions eliminated the need for heavy cutting equipment on-site, and the pallets could be easily moved to different floors of the building using standard tower cranes and pallet jacks, providing a level of logistical flexibility that a 5-ton coil could never offer.

From a handling perspective, flat packs are inherently more user-friendly. Most businesses are equipped with standard forklifts capable of safely lifting and transporting a palletized stack of sheets, which typically weighs between 1 and 3 tons. This accessibility removes the significant capital expenditure and facility modifications required for coil handling systems. However, this convenience comes with a trade-off. The additional processing involved—uncoiling, cutting to length, and stacking—means that the cost per kilogram of stainless steel in flat pack form is generally higher than in coil form. Furthermore, for manufacturing applications, using pre-cut sheets can lead to lower material yield, as the fixed dimensions may not be the most efficient layout for producing smaller components, resulting in more scrap waste.

| Feature | Coil Packaging | Flat Pack Packaging |

|---|---|---|

| Ideal Application | High-volume, automated manufacturing (e.g., automotive, appliance) | Custom fabrication, construction, smaller production runs |

| Handling Equipment | Specialized overhead cranes, C-hooks | Standard forklifts, pallet jacks |

| Storage | Requires significant, specialized space for heavy, large-diameter coils | More flexible; can be stored in standard pallet racking |

| Production Efficiency | High; enables continuous processing and minimal downtime | Lower; requires individual sheet loading, more changeover time |

| Material Waste | Lower; allows for optimal nesting of parts to minimize scrap | Higher; fixed sheet dimensions can lead to more offcut waste |

| Relative Cost | Lower cost per kilogram of raw material | Higher cost per kilogram due to additional processing |

Hybrid and Custom Solutions: Beyond the Basics

While coils and standard flat packs represent the two primary packaging formats, the reality of global trade and diverse manufacturing needs often calls for solutions that exist between these poles. At MFY, we recognize that a one-size-fits-all approach is insufficient. This is where hybrid and custom solutions become invaluable. These can include options like "pancake" coils—which are narrower and lighter than standard coils—or custom-sized flat packs tailored to a specific project's dimensions to minimize waste. We can also create mixed shipments, combining a large coil for a main production line with a small, crated flat pack for a related custom job, all within a single delivery. This flexibility is key to optimizing a client's specific supply chain.

A compelling example of this is a project we undertook for a client in a remote region of Russia. They were manufacturing components for the energy sector and faced significant logistical constraints. The roads to their facility could not accommodate the large trucks required to transport standard 10-ton coils, and their on-site equipment was not capable of handling such weights. Instead of viewing this as an insurmountable problem, our logistics and production teams collaborated with the client to develop a custom solution. We produced smaller, 2.5-ton "pancake" coils that were narrow enough to be loaded two-across on smaller, more maneuverable trucks. Furthermore, we designed reinforced, weatherproof crating for these coils to protect them from the harsh climate and rougher transport conditions, ensuring the material arrived in pristine condition and ready for their specific production needs.

However, it is crucial to approach customization with a critical and strategic mindset. While tailor-made packaging offers unparalleled flexibility, it can introduce variables that affect both cost and lead times. The engineering and material adjustments for non-standard packaging require additional resources and planning. Therefore, a successful custom solution hinges on deep collaboration between the supplier and the client. This involves a detailed discovery process where we, as the supplier, must fully understand the client’s end-to-end process: from the transport route and unloading capabilities to the specific machinery and production workflow. Clear and precise communication in the purchase order and technical specifications is paramount. This collaborative effort ensures that the final packaging is not just a container, but a purpose-built tool that solves unique logistical challenges and enhances the client's operational efficiency, justifying the investment in a non-standard approach.

Coils boost automated production efficiencyTrue

Automated stamping lines using coils eliminate sheet-change downtime and reduce material waste from offcuts.

Flat packs require specialized cranesFalse

Standard forklifts can handle flat packs, unlike coils which need C-hooks or overhead cranes.

How do different packaging materials like PE film and paper affect the quality and safety of stainless steel sheets?

Are you worried that the flawless finish on your stainless steel sheets will be ruined by scratches or corrosion before it even reaches your production floor? This damage, often caused by inadequate protective materials, can lead to costly rejections. Understanding the nuances of PE film versus paper is essential.

Polyethylene (PE) film provides superior protection against moisture and abrasion, crucial for high-value finishes and long sea voyages. In contrast, paper interleaving offers a basic, cost-effective barrier against scratches, suitable for standard finishes and less demanding transit conditions, directly impacting final material quality.

The choice between a polymer film and a simple paper sheet is a decision loaded with consequence, especially when dealing with stainless steel, a material often chosen for its aesthetic properties. I remember a case with a client in Southeast Asia, a manufacturer of high-end elevators. Their initial shipments, using standard paper interleaving, repeatedly suffered from "water staining"—a form of localized corrosion caused by trapped moisture during the humid sea transit. This resulted in a rejection rate of nearly 15%. After consulting with our technical team, we switched them to a PE film with a specific low-tack adhesive. The result was immediate: their rejection rate dropped to zero. This experience was a powerful lesson in how the microenvironment created by the packaging material is just as critical as the external crating. It’s a delicate balance between chemistry, material science, and logistics, and getting it right is fundamental to delivering on the promise of quality.

Delving deeper into this topic requires us to move past a simple "good vs. bad" comparison and instead adopt the perspective of a material scientist. The interaction between the protective layer and the stainless steel surface is a complex interplay of physical and chemical factors. The surface of a stainless steel sheet, especially one with a delicate finish like a mirror or brushed texture, is highly susceptible to both mechanical damage and chemical attack. The chosen interleaving material must address both threats without introducing new problems, such as adhesive residue or chemical leaching. The decision-making process must therefore be informed by a technical understanding of the materials themselves, the specific grade and finish of the steel, the anticipated transit conditions, and the end-user's processing requirements. This analysis will explore the distinct properties and applications of PE film and paper, providing a robust framework for making an informed and effective choice.

The Protective Role of Polyethylene (PE) Film

Polyethylene (PE) film2 is the premier choice for protecting sensitive stainless steel surfaces. Unlike paper, it creates an impermeable barrier against moisture, a critical feature for preventing water spots and galvanic corrosion, especially during long ocean transits through varying climates. The film adheres directly to the steel surface, ensuring that it remains in place and provides continuous protection against scratches, scuffs, and abrasions from handling. This adhesive quality is precisely engineered; the "tack" or stickiness is strong enough to hold fast during transport but gentle enough to allow for clean removal without leaving adhesive residue, which can be a costly and time-consuming problem to fix.

The versatility of PE film is one of its greatest strengths. At MFY, we don't just offer one type of film; we provide a range of solutions tailored to the application. For clients using fiber laser cutting machines, we supply a specialized laser-cuttable PE film. This film can withstand the intense heat of the laser without melting or creating noxious fumes, allowing the protective layer to remain on the sheet during the entire cutting process, thus protecting it until the very last moment. For architectural applications where panels might be stored outdoors temporarily, we offer films with UV inhibitors that prevent the film from degrading and becoming difficult to remove after sun exposure. The film's thickness, measured in microns (µm), is another customizable variable, typically ranging from 40 to 100 µm, chosen based on the value of the finish and the expected severity of handling.

Consider a client of ours who manufactures luxury kitchen appliances. They use a No. 8 mirror-finish stainless steel3, where even the slightest imperfection is cause for rejection. For them, a standard paper interleaving is simply not an option. We supply their material with a 70-micron, low-tack, clear PE film. This not only provides flawless protection from our facility to theirs but also allows for visual inspection through the film. The cost of this premium protection is a fraction of the cost of a single rejected appliance panel, making it an essential investment rather than an expense. This case demonstrates that for high-value aesthetic applications, the advanced protective capabilities of PE film are indispensable for quality assurance.

Paper Interleaving: The Traditional Choice

Paper has been the traditional material for interleaving stainless steel sheets for decades, and for many applications, it remains a viable and cost-effective solution. The most common type used is acid-neutral kraft paper. The "acid-neutral" property is crucial; acidic paper can react with the chromium oxide passive layer on the stainless steel, leading to staining or corrosion over time. The paper acts as a simple physical separator, preventing the metal-on-metal contact that causes scratches as sheets shift and vibrate during transit. It is breathable, which can be an advantage in some circumstances, as it prevents a complete seal where condensation could potentially be trapped.

The most significant evolution in paper protection is the development of Volatile Corrosion Inhibitor (VCI) paper. This isn't just a physical barrier; it's an active corrosion prevention system. VCI paper4 is impregnated with chemical compounds that sublimate, or turn into a gas, within the enclosed package. This vapor is attracted to the metal surface, where it condenses and forms a thin, invisible molecular layer. This layer disrupts the electrochemical process of corrosion, effectively protecting the steel from moisture, salt, and other airborne contaminants. After unpacking, the VCI layer dissipates from the steel surface, leaving it clean and ready for use without any need for additional cleaning.

VCI paper is an excellent middle-ground solution. For a manufacturer of internal, non-visible components for industrial machinery, a perfect aesthetic finish is not required, but protection against rust during a three-month storage period is essential. In this scenario, a full PE film might be overkill and unnecessarily expensive. A full wrap with VCI paper provides the necessary corrosion resistance at a lower price point. For example, industry data shows VCI paper can add as little as $2-$5 per ton to the packaging cost, whereas a high-quality PE film can add $10-$20 per ton. This makes VCI paper a strategically sound choice for applications where corrosion is a greater risk than minor surface abrasion.

| Protective Material | Primary Function | Ideal Use Case | Relative Cost | Key Limitation |

|---|---|---|---|---|

| Standard Kraft Paper | Physical separation | General purpose, low-risk transit, non-critical finishes | Low | Offers minimal moisture and corrosion protection |

| VCI Paper | Active corrosion inhibition | Long-term storage, high-humidity environments, industrial parts | Medium | Does not prevent heavy scratches; effectiveness can degrade |

| Standard PE Film | Abrasion & moisture barrier | Decorative finishes (2B, No.4), moderate handling | Medium-High | Can trap moisture if not applied properly; residue risk |

| Laser-Cuttable PE Film | In-process protection | Clients using fiber laser cutters | High | Higher cost; specialized for a specific manufacturing process |

| UV-Resistant PE Film | Abrasion & UV protection | Architectural panels, outdoor storage | High | Over-specification if there is no sun exposure |

Critical Comparison: PE Film vs. Paper in Practice

The choice between PE film and paper is not binary; it's a spectrum of risk versus cost. PE film offers a far superior physical barrier. Its tear and puncture resistance are significantly higher than paper's, providing robust protection against the kind of damage that can occur from a dragging forklift tine or a dropped tool. We commissioned a simple test where a 50-micron PE film and a standard kraft paper interleaving were subjected to a standardized abrasion test. The PE film withstood over 200 cycles before showing any sign of failure, while the paper was compromised in under 30 cycles. This data quantifies the superior mechanical protection offered by film, which is vital for maintaining the integrity of delicate brushed or polished finishes.

However, the application process of PE film itself requires precision. If the steel surface is not perfectly clean and dry before the film is applied, contaminants or moisture can be trapped underneath, leading to defects that only become visible upon removal. This is why at MFY, our film application lines are housed in a controlled environment to ensure a flawless bond. Paper, being more forgiving, is simply laid between sheets, a less technically demanding process. Furthermore, environmental considerations are becoming increasingly important. Paper is generally easier to recycle than PE film, a factor that is important to many of our clients with corporate sustainability goals.

Ultimately, the decision must be holistic. For a shipment of 304 2B finish sheets—a standard unpolished surface—going to a fabricator of restaurant equipment in a dry climate via a short road journey, VCI paper is an excellent, cost-effective choice. It provides the necessary corrosion protection without the expense of film. Conversely, for a shipment of 316L mirror-finish sheets traveling by sea to a luxury yacht builder in the Middle East, a high-tack, UV-resistant PE film is the only responsible choice. The potential cost of a single rejected panel due to a scratch or water stain would dwarf the entire cost of the premium packaging. The key is to analyze the entire value chain and select the material that delivers the lowest total cost of ownership, not just the lowest price per meter.

PE film prevents moisture damageTrue

PE film creates an impermeable barrier that effectively blocks moisture, preventing water spots and galvanic corrosion on stainless steel sheets.

Paper is better than PE filmFalse

While paper has its uses, PE film offers superior protection against both abrasion and moisture, especially for high-value finishes and long transits.

What are the impacts of packaging choice on transportation and logistics for stainless steel sheets?

Are you factoring logistics into your packaging decisions? A failure to do so can lead to a cascade of problems, from rejected shipments at the port to overloaded trucks and handling accidents. These are expensive, entirely preventable logistical failures that start with the wrong packaging choice.

Packaging choices critically impact transportation by altering shipment weight and volume, which dictates freight costs. They also determine handling requirements at ports and warehouses and the feasibility of different transport modes, directly influencing overall logistical speed, safety, and expense.

The connection between a crate's design and a ship's stability might seem distant, but in my world, they are directly linked. I once managed a large order for an engineering contractor in Russia destined for a project site accessible only by a combination of sea, rail, and a final, grueling leg by truck over rough terrain. The initial plan called for standard 3-ton flat-packed crates. However, our logistics team flagged that the local rail cars had a lower weight capacity per axle and the "last-mile" trucks had liftgate limitations. We had to re-engineer the entire packaging plan, shifting to smaller, 1.5-ton reinforced crates. This decision increased the number of packages but ensured each one could be handled safely and efficiently at every interchange point. It was a powerful reminder that packaging is not just about protection; it is a critical interface with every link in the logistical chain, and it must be designed with the entire journey in mind.

The journey of a stainless steel sheet5 from our mill in China to a client's facility in India or the Middle East is a complex ballet of logistics. The packaging is not a passive passenger in this journey; it is an active participant that determines how the product can be moved, stored, and protected. A critical analysis of this topic must therefore extend beyond the factory gates to encompass the entire global supply chain. We need to dissect how packaging decisions influence tangible costs, such as freight rates calculated by weight and volume, and intangible risks, like customs delays and in-transit damage. This involves understanding the specific demands of different transportation modes—the dynamic forces of ocean shipping, the weight constraints of road and rail, and the meticulous documentation required for international customs clearance. By examining these factors in detail, we can illuminate how strategic packaging becomes a powerful tool for logistical optimization.

Weight, Volume, and Freight Cost Optimization

Every kilogram added by packaging is a kilogram you pay to ship. This is the fundamental equation of freight cost. While robust packaging like a full wooden crate offers maximum protection, it also significantly increases the gross weight and volume of a shipment, a concept known as tare weight. For instance, a standard wooden crate for a 2-ton pallet of stainless steel sheets can weigh between 100 to 150 kg. For a large order of 100 tons, that's an additional 5 to 7.5 tons of pure packaging weight. In contrast, a "skid-only" package with protective wrapping might only add 30-40 kg per pallet. While this seems minor, on a large scale, it can mean the difference between fitting an order into four shipping containers instead of five, a substantial cost saving.

The relationship between weight, volume, and cost is governed by the concept of "chargeable weight." Ocean and air freight carriers charge based on either the actual gross weight or the volumetric weight (also called dimensional weight), whichever is greater. A large but light crate can be more expensive to ship than a small, heavy one. At MFY, we use specialized software to model our packaging solutions to optimize this ratio. For a client shipping to a high-cost freight lane, we might design a more compact, dense package that minimizes volumetric weight, even if it requires more sophisticated internal bracing to ensure safety.

A practical example is how we load ocean containers. A standard 20-foot container has a maximum payload of around 25 tons. We can typically load eight 3-ton coils ("eye to the sky") or about ten to twelve 2-ton flat-packed pallets. The packaging format and dimensions directly dictate the loading plan. If a client's custom crate dimensions are inefficient, it can lead to "dead space" in the container, meaning they are paying to ship air. We recently worked with a distributor in Southeast Asia to redesign their standard pallet size, reducing its length by just 10 cm. This small change allowed us to fit an entire extra pallet into each container, reducing their per-unit shipping cost by nearly 8%.

Handling and Modal Choice: From Sea Freight to Last-Mile Delivery

The choice of packaging is inextricably linked to the equipment and infrastructure available along the transport route. A 10-ton stainless steel coil packaged "eye to the side" for horizontal transport requires a specialized C-hook or a specific type of forklift boom to be loaded and unloaded. An "eye to the sky" coil needs an overhead crane with a different attachment. If a client’s facility is only equipped with standard forklifts, ordering a coil, no matter how cost-effective the material itself, is a non-starter. This is a primary consideration in our initial discussions with any new customer; we must match the packaging to their certified handling capabilities to prevent accidents and damage.

The rigors of different transport modes also place unique demands on the packaging. Ocean freight is the most challenging environment. A ship at sea is in constant motion, subjecting the cargo to dynamic forces: heave (vertical), sway (lateral), surge (longitudinal), pitch, roll, and yaw. Packaging must be incredibly robust, with secure internal and external strapping and blocking, to prevent cargo from shifting and breaking loose inside a container. For a client in India, we ship coils that are blocked and braced with heavy-duty timber inside the container, a method certified by marine surveyors to withstand the turbulent monsoon season sea conditions.

This contrasts with road and rail transport, where the primary forces are vibration and shock from acceleration and braking. Here, the focus shifts to preventing abrasion between sheets and ensuring pallets or crates are securely fastened to the truck bed or rail car floor. The final delivery to a construction site, as in the case of our Middle Eastern client, presents another set of challenges. The packaging must be maneuverable enough for smaller vehicles and cranes and potentially weather-resistant if it needs to be staged outdoors. The optimal packaging solution is therefore one that is robust enough for the harshest leg of the journey while being practical for the final destination.

| Transport Mode | Primary Risk | Key Packaging Requirement | MFY Solution Example |

|---|---|---|---|

| Ocean Freight | Corrosion, Dynamic Forces (Roll/Pitch) | Waterproof wrapping (VCI, film), container blocking & bracing | Marine-certified timber bracing for coils destined for India during monsoon season. |

| Rail Freight | Vibration, Shunting Shock | Anti-abrasion interleaving, secure pallet strapping | Use of high-density foam inserts and heavy-duty polyester strapping for long-distance rail shipments. |

| Road Freight | Shock, Vibration, Weather | Secure fastening to truck bed, weatherproof shrouding | Non-slip pallet mats and heavy-duty, UV-resistant waterproof wrapping for flatbed truck transport. |

| Air Freight | Weight & Volume Limits | Lightweight materials, extreme space efficiency | Custom-built, lightweight reinforced cardboard crates ("air-crates") for urgent, high-value sheets. |

Navigating International Standards and Customs

A shipment can be perfectly packaged for protection and transport, but if it fails to meet the destination country's import regulations, it will be stopped at the border. The most critical of these is the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This global standard requires that all solid wood packaging materials (WPM), such as pallets, crates, and dunnage, be heat-treated or fumigated to kill insects and prevent the spread of pests. Every piece of wood packaging we use for export at MFY is ISPM 15 compliant, clearly stamped with the internationally recognized mark. Failure to do so can result in customs authorities refusing entry, forcing the cargo to be fumigated at the client's expense, or even ordering it to be re-exported.

Beyond wood treatment, accurate and clear documentation that aligns with the physical packaging is vital for smooth customs clearance. This includes precise weight declarations (both gross and net), the exact number of packages, and a detailed packing list that corresponds to the markings on the crates. For a complex order with multiple types of stainless steel grades or sizes, we use a system of color-coded labels and unique package identifiers. This allows customs officials—and our clients—to easily identify the contents of each crate without having to open all of them.

We had a case with a large engineering contractor where their order comprised over 50 different line items, all packed into 30 distinct crates. Our logistics team created a detailed "master packing list" that cross-referenced each crate's unique number with its contents, weight, and dimensions. Each crate was labeled with this number and a scannable QR code linking to the specification sheet. The client's receiving team later told me this system saved them two full days of work in sorting and verifying the materials upon arrival. This level of logistical precision, embedded within the packaging strategy, is a core part of the service we provide, transforming packaging from a mere container into a tool for administrative efficiency.

Packaging affects freight costsTrue

Freight costs are calculated based on both weight and volume, making packaging design a key cost factor.

All wood packaging requires ISPM 15False

Only solid wood packaging materials for international shipping require ISPM 15 compliance, not all wood packaging.

What measures can companies take to ensure optimal packaging for stainless steel sheets?

You've meticulously specified the grade and finish of your steel, but did you apply the same rigor to its packaging? Neglecting this final step is like building a strong house on a weak foundation. It exposes your valuable investment to unnecessary risk, potentially erasing your hard-won margins overnight.

To ensure optimal packaging, companies must create detailed specifications in their purchase orders, conduct a thorough needs assessment, collaborate closely with a capable supplier like MFY, and implement a rigorous inspection protocol upon receipt of the goods. Proactivity is key.

This proactive approach is something I champion in every client consultation. I recall a new partnership with a large construction contractor who was procuring materials for a landmark building. Their RFQ was incredibly detailed on the steel's technical specifications but simply stated "standard export packing." I personally reached out and walked their procurement manager through a packaging checklist, asking about their unloading equipment, site storage conditions, and production schedule. Together, we co-developed a custom crating solution with specific lifting points and weatherproofing. Three months later, he called to thank me; a sudden tropical storm had swept through the construction site, but the steel, stored outdoors, remained in perfect condition, preventing a costly project delay. This experience solidified my belief that packaging isn't an afterthought; it's a collaborative dialogue essential for success.

Ensuring optimal packaging is not a passive activity where one simply trusts in a vague "standard." It is an active process of risk management6 and quality assurance that begins long before the steel is even produced. It requires a fundamental shift in mindset, from viewing packaging as a cost to be minimized to seeing it as an investment in protecting a far more valuable asset. This deep dive will outline a systematic approach that empowers you, the buyer, to take control of this critical process. We will break down the essential components of a robust packaging specification, explore the dynamics of effective supplier collaboration, and detail the best practices for receiving and inspection. This is not just a theoretical exercise; it is a practical roadmap, built from years of experience at MFY, designed to equip you with the tools and knowledge to safeguard your investment from our door to yours.

The Power of a Detailed Purchase Order Specification

The purchase order (PO) is more than a commercial document; it is a legally binding contract that should contain the complete technical specifications for your order, and packaging is a critical part of that. Relying on ambiguous terms like "standard export packing" or "seaworthy packing" is a significant risk. These terms are subjective and can be interpreted differently by various suppliers. To eliminate ambiguity, your PO must be explicit. A best-in-class packaging specification is a detailed checklist that forms an integral part of the procurement contract.

This specification should begin with the macro choices: format (e.g., coils or flat-packed sheets), and maximum weight per coil or pallet, which must align with your handling capabilities. Then, it should detail the protective layers. If you require film, specify the type (e.g., laser-cuttable PE), thickness in microns, and even the level of tack. If you require paper, specify if it must be acid-neutral or VCI-impregnated. Don't stop there. Detail the external protection: specify the type and thickness of waterproof wrapping, whether hardboard protection is needed, and the type of strapping (steel or polyester) and its configuration.

For all wood packaging materials, including pallets and crates, the PO must explicitly state the requirement for ISPM 15 compliance, complete with the appropriate stamp. ly, the specification should outline the labeling requirements. This includes the information to be displayed on each package: PO number, material grade, dimensions, weight (net and gross), and any special handling instructions. By providing this level of detail, you leave no room for error and create a clear standard against which the supplier's performance can be measured. It transforms the PO into a powerful quality assurance tool.

Supplier Collaboration and Audits

Choosing the right supplier is arguably the most critical step in ensuring optimal packaging. A reliable partner, like MFY, will not just passively accept your specifications; they will actively engage with them, ask clarifying questions, and use their expertise to suggest improvements. During the procurement process, you should treat packaging capability as a key supplier selection criterion. Ask potential suppliers about their standard packaging procedures. Request sample photos or even videos of how they pack materials similar to your order. A transparent supplier will be happy to provide this.

For significant or long-term contracts, don't hesitate to go further. A supplier audit, either conducted by your own team or a third-party inspection agency, can be invaluable. This doesn't necessarily mean a full-scale facility inspection. It can be a "pre-shipment inspection" where an agent verifies that the packaging for your specific order has been executed according to the PO specifications before it is loaded into the container. At MFY, we have a standard internal process where we take detailed, step-by-step photographs of the packaging process for every order. We document the material before packing, each layer of protection being applied, and the final state before the container is sealed. We proactively send this photo report to our clients, providing them with peace of mind and a documented record of quality assurance.

This collaborative relationship builds trust and prevents problems. A supplier who understands your business—your climate, your logistical challenges, your end-product's quality requirements—can become a valuable consultant. They can advise on new packaging innovations or warn you if a requested specification, while seeming robust, might have unintended negative consequences, such as being difficult to recycle or unpack safely. This partnership approach transforms the supply chain from a simple transaction into a shared commitment to quality.

| Action Item | Description | Why It's Critical |

|---|---|---|

| Needs Assessment | Internally evaluate handling equipment, storage environment, and transit risks. | Aligns packaging choice with your actual operational reality and risk profile. |

| Detailed PO Spec | Define every element: format, weight, materials (film/paper), crating, ISPM 15, labeling. | Creates a legally binding quality standard and eliminates ambiguity for the supplier. |

| Supplier Vetting | Ask for packaging photos, procedures, and client references. Treat packaging as a key capability. | Ensures you partner with a supplier who takes packaging as seriously as you do. |

| Pre-Shipment Photos | Require the supplier to provide a photographic report of your order being packed. | Provides visual verification that your specifications were followed before shipment. |

| Receiving Inspection | Train staff to inspect packaging before unloading and document any damage immediately. | Protects your right to file a freight claim and holds carriers and suppliers accountable. |

Implementing a Rigorous Receiving and Unpacking Protocol

The chain of responsibility for packaging does not end once the supplier seals the container. Your company's receiving department is the final and most critical quality control checkpoint. A thorough receiving protocol is your last line of defense against accepting damaged goods and your primary tool for recourse in the event of a problem. Your staff should be trained to conduct a two-stage inspection. The first stage happens before the container is even unloaded. They should inspect the container's seal for integrity and check the container itself for any major external damage that might indicate a rough transit.

Once the doors are opened, and before anything is removed, they should take photographs of how the cargo is situated. If there is any evidence of shifting, collapsed crates, or water ingress, this must be documented immediately. The second stage of inspection occurs as each package (coil or pallet) is unloaded. Each unit should be checked for external damage—punctures in the wrapping, broken straps, or crushed corners on crates. Any such damage must be noted on the bill of lading or proof of delivery before signing it. A simple signature without notation legally signifies that you have received the goods in good condition, which can forfeit your right to file a freight claim later.

ly, the unpacking process itself requires care. Staff should be trained on the correct way to cut strapping safely to avoid the "spring back" effect, which can cause injury and damage the steel. They should know how to lift sheets off a pallet without dragging them across the one below, which is a common source of scratching. If PE film is used, they should be instructed on the proper technique for removal to avoid leaving adhesive residue. A simple, one-page checklist and brief training session for the receiving team is a high-leverage activity that protects the material at its most vulnerable point.

Packaging is a collaborative dialogueTrue

Effective packaging requires active collaboration between buyer and supplier to address specific handling and storage needs.

Standard packing terms eliminate ambiguityFalse

Vague terms like "standard export packing" are subjective and open to interpretation, which is why detailed specifications are crucial.

What are the best practices for selecting the most suitable packaging standard for stainless steel sheets?

Faced with a dizzying array of packaging options, how can you be certain you are making the smartest choice for your business? Choosing incorrectly can silently eat away at your profits through material waste, production delays, or damage claims. Following a set of established best practices is the only way to ensure an optimal, cost-effective outcome.

Best practices for selecting packaging include a holistic assessment of your end-use, transit conditions, and handling capabilities. It involves balancing the upfront cost against the total risk of damage and waste, and critically, leveraging your supplier's expertise as a collaborative partner.

The most successful client relationships I've built are those where the conversation about packaging is a strategic dialogue, not a line item on a purchase order. It's about thinking through the entire lifecycle of the steel. I often use the analogy of choosing the right tool for a job: you need to match the tool to the specific task, the material, and the working environment. A low-cost packaging solution for a high-value, mirror-finish architectural panel is like using a hammer to drive a screw—it’s a fundamental mismatch that invites failure. By framing the decision within a strategic framework that considers the total cost of ownership, we can move beyond simply "buying steel" to intelligently investing in a solution that guarantees the material arrives ready to perform its function, thereby protecting the client's investment and reputation.

Selecting the right packaging is a multi-faceted decision that requires a blend of technical knowledge, logistical awareness, and financial acumen. It is not about finding a single "best" standard, as no such thing exists7. Instead, the goal is to identify the most suitable standard for a specific application, a specific journey, and a specific client. This requires a structured approach that moves beyond gut feelings and simple cost comparisons. This final deep dive will synthesize the concepts we've discussed into a practical decision-making framework. We will explore how to match packaging directly to your end-use, introduce the critical concept of Total Cost of Ownership (TCO) analysis8, and reinforce the immense value of leveraging your supplier as a strategic partner to create a solution that is not only effective today but also prepared for the challenges of tomorrow.

A Decision Framework: Matching Packaging to End-Use

The foundation of a good packaging decision is a clear understanding of the stainless steel's final application. The requirements for a structural component hidden inside a machine are vastly different from those for a gleaming decorative façade. You can use a simple decision tree approach to guide your thinking. The first question should always be: "Is the surface finish a critical aesthetic component?" If the answer is yes (e.g., for architectural panels, high-end appliances, elevator interiors, yacht fittings), then your choice is immediately narrowed to premium protective options. A high-quality, non-residue PE film becomes non-negotiable.

If the surface is not aesthetically critical, the next question is: "What are the primary risks during transit and storage?" If the material will face a long sea voyage, high humidity, or extended storage time, then corrosion becomes the primary enemy. In this case, VCI paper or film becomes the priority. If the transit is short and the climate controlled, but the material will be handled multiple times, then physical protection against scratches and dents takes precedence, suggesting a robust wrapping or even crating might be necessary.

ly, consider your production process. If you have an automated decoiling and stamping line, ordering coils is the only logical choice to maximize efficiency. If you are a custom fabrication shop performing manual cutting and welding, then receiving manageable, pre-cut flat sheets is essential to your workflow. By systematically answering these questions—about aesthetics, risk, and process—you can logically filter through the options and arrive at a solution that is intrinsically aligned with your specific operational needs, avoiding the common pitfalls of over-specifying (and overpaying) or under-specifying (and risking damage).

Total Cost of Ownership (TCO) Analysis

The most common mistake in procuring packaging is focusing solely on the upfront cost. The cheapest packaging is rarely the most cost-effective. A sophisticated buyer analyzes the Total Cost of Ownership (TCO), a framework that considers all direct and indirect costs associated with the packaging choice over its entire lifecycle. This includes not just the price of the paper or film but also the potential costs of failure: the value of rejected material, the labor costs for sorting damaged goods, production downtime caused by material shortages, freight claim processing costs, and the reputational damage from delivering a flawed final product.

Let's consider a practical, albeit simplified, TCO analysis for a hypothetical shipment of 20 tons of 304 BA (Bright Annealed) finish sheets valued at $60,000, shipped by sea to a humid climate. Option A uses basic paper interleaving at a cost of $100. Option B uses a premium VCI-backed PE film at a cost of $400. Based on historical data, the cheap paper carries a 5% risk of significant moisture damage, potentially affecting 20% of the shipment. The premium film has a near-zero risk. The TCO calculation reveals the hidden danger of the "cheaper" option.

| Cost Component | Option A (Cheap Paper) | Option B (Premium Film) |

|---|---|---|

| Upfront Packaging Cost | $100 | $400 |

| Value of Material at Risk | $60,000 x 20% = $12,000 | $0 |

| Probability of Damage | 5% | 0.1% |

| Expected Financial Loss (Risk) | $12,000 x 5% = $600 | $60,000 x 0.1% = $60 |

| Total Cost of Ownership | $100 (Cost) + $600 (Risk) = $700 | $400 (Cost) + $60 (Risk) = $460 |

This analysis clearly demonstrates that the more expensive initial packaging (Option B) actually presents a lower Total Cost of Ownership by effectively mitigating the high financial risk of material damage. Performing this type of TCO analysis shifts the conversation from "How can we cut packaging costs?" to "How can we invest in packaging to best protect our overall profit margin?"

Leveraging Supplier Expertise for a Future-Proof Solution

ly, one of the most powerful best practices is to stop viewing your supplier as a mere vendor and start treating them as a strategic partner. A knowledgeable and experienced supplier like MFY has a wealth of data and anecdotal experience from serving hundreds of clients across dozens of industries and countries. This expertise is a free and invaluable resource that you should actively leverage. Be transparent with your supplier. Share your challenges, your end-use requirements, and even your "pain points" from past experiences.

A true partner will use this information to co-create a solution with you. I recall a client, a mid-sized manufacturer, who had always ordered flat packs. During a business review, they mentioned plans to invest in an automated cutting line within the next two years. Hearing this, we proposed a transitional strategy. We suggested they begin ordering smaller, lighter "pancake" coils. This would allow them to start realizing some material yield benefits immediately, and more importantly, it would allow their team to gradually develop the skills and processes for handling coiled material. When their new equipment arrived 18 months later, they were fully prepared to make the switch seamlessly, without the steep and disruptive learning curve they would have otherwise faced.

This is the essence of a future-proof solution. It's about looking beyond the immediate order to where your business is heading. A good supplier helps you anticipate future needs and build a supply chain that is not just efficient for today, but also resilient and scalable for tomorrow. By fostering an open, collaborative dialogue, you can transform the simple act of specifying packaging into a strategic advantage that supports your long-term growth.

Packaging choice affects total costsTrue

The article demonstrates through TCO analysis how packaging decisions impact not just initial costs but also potential damage risks and associated expenses.

One packaging fits all situationsFalse

The article emphasizes there's no universal "best" standard - packaging must be matched to specific end-use, transit conditions and handling requirements.

Conclusion

Ultimately, viewing packaging not as a final step but as an integral part of your procurement strategy is key. A thoughtful choice, made in collaboration with your supplier, protects your investment, streamlines your operations, and ensures your stainless steel performs exactly as you intended.

-

Understand industry benchmarks for stainless steel sheet packaging ↩

-

Learn about the protection advantages and applications of PE film in logistics ↩

-

Explore the uses and qualities of a No. 8 mirror-finish in premium applications ↩

-

Understand how VCI paper works as a corrosion inhibitor for metals ↩

-

Understand logistics challenges when transporting stainless steel sheets globally ↩

-

Discover the strategies to enhance packaging as a proactive risk management process ↩

-

Learn why a single packaging standard isn't ideal for all stainless steel uses ↩

-

Understand Total Cost of Ownership to make informed packaging decisions ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.